We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Industrial Cable Spools and Cable Reels: Choosing Reels and Cable Handling Equipment

In most industries, the terms “cable spool," “cable reel," and “cable drum” are used interchangeably. Some manufacturers use “reel" to refer to the full unit, while “spool" refers to what’s left behind after the cable has been exhausted. For others, a “spool" refers to smaller units — for instance, data cables — while “reel" refers to larger drums.

Regardless of the terminology, cable reels play a critical role in electrical work, and low-quality spools or improper material handling equipment can easily drive up the cost of an installation project. In this article, we’ll explain how to use cable reels safely and efficiently while minimizing lost product.

Bulk Cable Reel Materials: Advantages and Drawbacks

Electrical cable reels are typically made from wood or steel (occasionally, plastic reels are used for lightweight materials intended for medical sites and other environments with strict hygiene requirements).

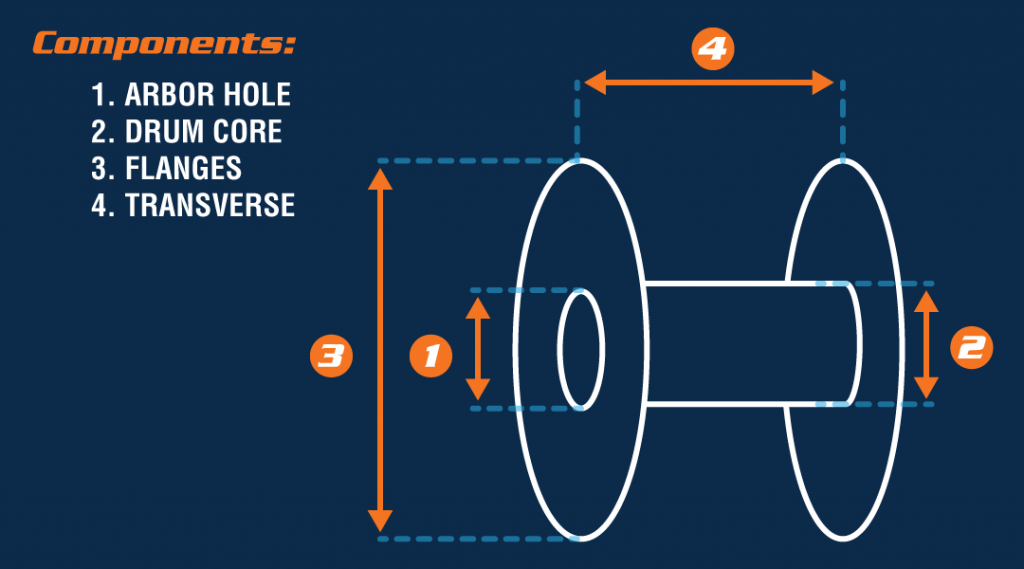

The basic components of a cable reel include:

- Flange - Typically circular, the flanges sit at either end of the core.

- Drum - The drum holds the cable, sometimes with integrated staves. Internal flanges may be used to create multiple compartments within a single reel (paralleling).

- Arbor Hole - An axle can be passed through the arbor hole for controlled payout.

Cable reels aren’t especially complex devices, but quality of construction makes a difference. The reels should be appropriate for the task at hand; wooden reels warp over time and have a shorter operational lifespan than steel reels. However, wooden reels are much less expensive, so they’re typically the better option for short-term use.

Regardless of the cable reel’s construction, high-quality material handling equipment is crucial for ensuring accurate, easy payouts and spooling.

Read More: Are Wooden Reels or Steel Reels Better for Bulk Cable Handling?

Cable Reel Sizing for Electrical Installation and Shipping

The National Electrical Manufacturers Association (NEMA) publishes standards for ideal steel reel sizes and other specifications related to cable reel selection. Those standards are copyrighted and can be purchased here.

When purchasing reels, electricians should base decisions on the outside diameter of the cable, the length of the cable order, the minimum safe bending radius of the conductor, and the total weight of the order. Steel reels are necessary for shipping, particularly when reels will be reused; BHS offers a range of steel cable reels designed to protect product during transit, payout, and spooling.

Read More: Steel Reel Sizes for Bulk Cable Orders

Products to Consider: BHS Steel Reels

Available in a variety of compartment configurations, BHS Reels are constructed of heavy-duty steel with a powder-coat finish. Pre-drilled cable slots can accommodate wire gauges from 0.75 inches to 1.12 inches, and custom sizes are available for special applications.

BHS Reels have hub plates with through-holes to allow multiple compartments to be locked together, and all reels are compatible with BHS wire and cable handling equipment (discussed below). All reels comply with NEMA guidelines for construction and handling.

Choosing Cable Reel Handling Equipment for Electrical Installation Applications

The right material handling equipment can improve efficiency at every step of the electrical supply chain. Whether you’re installing an electrical system at a greenfield site or managing upgrades to an established operation, your equipment will determine throughput — and the amount of materials lost during the process.

Cable Reel Stands and Pull Carts

Cable spools need to be protected during transit, and ideally, material handling equipment should facilitate smooth payout. Basic reel stands are a cost-effective solution for up to 5 reels (we’ll discuss additional paralleling solutions later in this article). Wire pull carts provide additional capacity and superior protection for materials.

Products to Consider: BHS Wire Pull Cart (WPC) and BHS Reel Stands

BHS Reel Stands are constructed from heavy-duty steel and engineered for high-capacity cable storage with tangle-free payout. Four-way fork pockets improve maneuverability, and thanks to the Reel Stand’s slim profile, optional casters allow cable reels & spools to move easily through narrow aisles and doorways. Reel Stands can hold up to five reels, and individual reel hubs can be locked for convenience.

The BHS Wire Pull Cart (WPC) is an excellent option for larger electrical installation projects that still require maneuverability. With four swivel casters, lifting eye bolts for moving between floors, and fork pockets, the WPC can hold up to 3,000 pounds of cable reels. PVC wire guides ensure smooth, efficient payout, and the unit can be padlocked to protect assets when not in use.

The Reel Taxi™ (RT-1424) makes Category 5 and 6 cable management easy. Adjustable for data cable spools between 12 and 24 inches, the Reel Taxi has swivel casters with foot-activated brakes and a small footprint for navigating tight corners. The interior of the frame has poly pads to protect cables, and the poly-coated rollers have sealed bearings to protect reel flanges while preventing slipping.

Cable Spool & Reel Storage Solutions

Electricians should look for cable reel storage solutions that protect assets while allowing for quick deployment. That’s especially important when cable needs to move off site for installation — common for electrical distributors — or when storage locations are expected to change frequently.

Products to Consider: BHS Cable Spool Storage and Payout Equipment

The Reel Sherpa™ Cradle (RSC-5K) has a 5,000-pound capacity, ideal for loaded reels of any type. It features an enclosed design that guards wire, cable, and spools during movement. A hinged ramp makes loading easy, and welded tie-down points allow for convenient storage. Ideal for use with dedicated payout solutions, the Reel Sherpa Cradle can be lifted with pallet jacks or lift trucks.

The Reel Sherpa™ Stacker (RSS-5K) is an industrial steel stand that can be lifted with pallet jacks or lift trucks (optional forklift pockets add security and protect assets during travel). Engineered as an alternative to chock-and-block processes, the Reel Sherpa Stacker has a small footprint that enables quick deployment. Ideal for storing paralleled reels.

Lifting Equipment for Cable Reels

On many worksites, maneuvering cable reels is the most difficult part of the job. Larger spools cannot be moved manually, particularly when operations have narrow aisles. Improper lifting equipment can easily cause material damage, so electricians should plan for transport during the earliest phase of the project.

Forklifts can be outfitted with specialized attachments to load reels into racking or to lift reels for overhead payout. These attachments modify existing equipment, so they’re cost-effective solutions — provided that they’re properly engineered.

Products to Consider: BHS Cable Reel Lifting Equipment for Lift Trucks

BHS offers a range of attachments that address different needs. The Reel Handler Attachment (RHA) is an effective option for lifting, loading, and transporting reels, equipped with anti-slide stops that protect materials during loading and unloading.

The Dyna Reel Platform Attachment (DRPA) is a portable reel-roller platform that can convert lift trucks into full-service payout solutions. For construction and distribution applications, the DRPA improves efficiency while adding flexibility.

Finally, the Overhead Reel Lifter (ORL) can lift reels of up to 5,000 pounds, ensuring clearance for overhead payout applications. The ORL features safety chains with spring-loaded clasps and slip hooks, adjustable keyhole slots, and an integrated storage tray.

Read More: Cable Reel Lifting Equipment for Forklifts: A Buying Guide

Paralleling Reels in Electrical Installation

In recent years, parallel reels have become standard in electrical work. The benefits are obvious: By spooling multiple cables on a master reel, electricians can take a single reel to the job site with different lengths of cable. Electricians spend less time maneuvering equipment, and fewer workers are needed to keep the task within its expected timeframe.

For optimal efficiency, reels should be able to spin independently without tangling or slippage. This is easier said than done: Precise engineering is necessary to keep cable and wire separated, and most operations will benefit from customized solutions. This is particularly applicable for electrical distributors that utilize paralleling to create value-added delivered solutions.

Read More: Parallel Wire Reels: How They Help Electrical Wholesalers (and Their Customers)

Products to Consider: BHS Equipment for Cable Reel Paralleling

The fully customizable Parallel Reel Payout (PRP) comes standard with four-way fork pockets and can be outfitted with optional casters for greater maneuverability. Its multi-compartment reels spin freely and independently, and shaft safety locks keep reels in place when not in use.

The Parallel Reel Payout Wagon (PRW) also allows parallel reels to be transported without additional material handling equipment. With a capacity of 5,000 pounds, it’s optimized for manual movement: The PRW has a slim profile that fits easily through 34-inch door openings, and reel configurations can be customized with both free-spinning and fixed-compartment reels.

For higher volume applications such as greenfield installation sites, the Parallel Reel Payout Trailer (PRP-TRL) is a complete turnkey solution. It holds two to three Parallel Reel Payouts, allowing construction electricians to work efficiently with preloaded cable. The PRP-TRL features smooth payout, precise controls, and a 360-degree turntable base.

The Spool Winding Trolley IIoT (SWT-IIoT) is ideal for electrical distributors looking for cut-to-length cable distribution. A standalone payout engine, its included software can be integrated into your existing IIoT system. The software tracks inventory while filling orders, and an integrated touchscreen allows for precise order processing. With numerous custom options, the SWT-IIoT can play a critical role in Industry 4.0 order fulfillment.

Find the Right Cable Reel Management Solutions for Your Operation

BHS, Inc.’s reel handling equipment lineup includes options for all types of electrical work. Custom configurations are available on request, and our focus on ergonomics helps to keep installers safe. To learn more, contact our sales team at 1.800.BHS.9500.

SM-1387 Industrial Cable Spools and Cable Reels Choosing Reels Cable Handling Equipment