We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Parallel Wire Reels: How They Help Electrical Wholesalers (and Their Customers)

But custom cable paralleling directly from the wire wall isn’t always possible. Distributors need to pull each conductor at the same time to create the paralleled delivery reel. When these cables or wires are halfway across the facility, they need a central collection point to pay out onto a final paralleled reel.

That’s what parallel wire reels make possible. Because they have multiple compartments, users can fill each with the precise order of each type of cable; then they can pay all the conductors together out onto a final reel, the one that will be delivered to the customer. Alternately, they can simply deliver the parallel reel, and the electricians can pull from multiple compartments at once at the jobsite.

Even so, many distributors still rely on standard wooden or steel reels, preferring to move whole master reels of product to provide custom paralleling services. That approach can work — but it’s hardly the best way to maintain a competitive edge. In addition to cutting down on the time (and cost) of custom parallelling, steel multi-compartment reels provide value in a variety of ways, both to distributors and their customers.

The Advantages of Steel Parallel Cable Reels

As the cable management industry has evolved, the advantages of high-quality reel payouts have become more obvious. Essentially, parallel reel equipment keeps runs of cable and wire separated while ensuring smooth, consistent payout. Installers can quickly access the exact length of cable they need, and free-spinning compartments minimize wasted product; perhaps most importantly, parallel wire reels are simply much easier to work with. Distributors have taken notice, offering custom parallel reels as a value-added service that dramatically improves throughput.

While some distributors originally used wooden reels for parallelling, steel reels are by far the better option. Custom paralleling requires more maneuvering and general interaction with the reels, which can severely stress wooden reels. When damaged, wooden reels can actually ruin their product, which results in lost time and money. Paralleling on damaged wooden reels can also lead to cable becoming tangled and unmanageable.

In contrast, steel parallel wire reels are intuitive and customizable for the task at hand. Parallel reels allow distributors to load multiple cables or wires for a construction job onto a single piece of equipment. This practice allows workers to have all necessary cable and wire products quickly accessible, saving them time and space at the jobsite.

Choosing and Customizing Parallel Wire Reels

Of course, as is the case with all material handling equipment, the quality of the product makes a profound difference. To use parallel reels effectively, workers need equipment that’s customized for the task at hand. Parallel reel systems aren’t designed for a single use — they’re an investment, and as such, they need to be meticulously engineered to ensure years of dependable service.

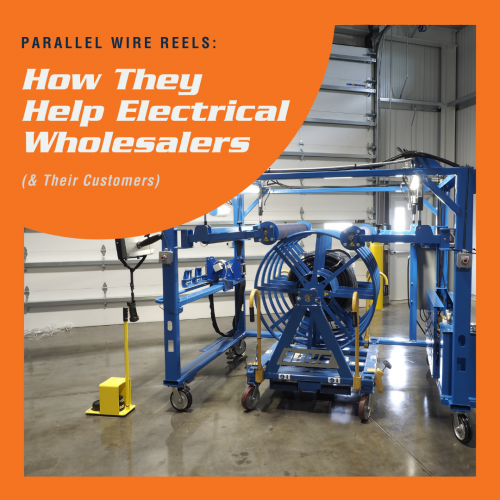

The BHS Parallel Reel Payout (PRP), Parallel Reel Payout Wagon (PRW) and Spool Winding Trolley with Industrial Internet of Things (SWT-IIoT) provide distributors with excellent opportunities to provide customers with value-added services that dramatically improve throughput. The products dramatically improve throughput on the job site, and each can be customized as necessary to meet the needs of different types of work:

- The Parallel Reel Payout (PRP) features multiple, free-spinning reel compartments to streamline cable pulling. Fully customizable, it comes standard with four-way fork pockets for easy transport. Optional casters allow for manual maneuverability, and narrow models are available to fit 34" minimum door openings.

- The Parallel Reel Payout Wagon (PRW) is optimized for high-volume cable reels. Heavy-duty casters allow for maneuverability, and with a max carry weight of 5,000 pounds, the PRW simplifies large cable/wire projects by giving workers the resources they need to stay productive.

- The Spool Winding Trolley IIoT (SWT-IIoT) offers an effective means of adding cable pulling equipment to an Industry 4.0 order fulfillment system. The SWT-IIoT creates a continuous information chain from the customer’s request to the payout floor, allowing distributors to harness the power of data to improve cut-to-length infrastructure.

Each product is engineered for durability and for seamless integration into existing workflows. Crucially, BHS parallel wire reel systems can be equipped with virtually any combination of reels for specific applications, making them an ideal choice for custom paralleling.