We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Cable Reel Lifting Equipment for Forklifts: A Buying Guide

The most obvious solution is to use existing heavy-duty equipment — namely, lift trucks — equipped with dedicated attachments designed to handle electrical reels. However, cable-specific forklift attachments vary greatly in both design and quality. Buyers should carefully research the features of the attachment: Will it be used during payout, or simply for transporting reels in the field and on the floor? Is it compatible with different reel sizes, and will it keep products and workers safe when the lift truck is in motion?

To choose an appropriate solution for your operation, consider how different BHS options accomplish this important task:

Reel Handler Attachment (RHA) - Most basic transport needs can be addressed by the Reel Handler Attachment, an essential piece of equipment for lifting, transporting, and loading reels into racking. Operators roll the reel onto the RHA, using the front reel stop to lock the product into place. The anti-slide rear stop ensures stability, while tapered ends protect the reel and its contents during loading.

When attached to a forklift with a sufficient capacity, the RHA allows an operation to take advantage of racks and maximize utilization of vertical space. However, other lifting attachments may provide a better long-term value for operations that need payout and spooling.

Dyna Reel Platform Attachment (DRPA) - For basic cable reel handling with added payout capabilities, the Dyna Reel Platform Attachment is an efficient, safe, and portable choice. Steel rollers allow for ergonomic payout and spooling, and tapered forks simplify loading tasks. An optional tie-down kit adds even more security.

The DRPA is compatible with Spool Winding Trolleys and Spooling Caddies. Engineered as an affordable full-service payout solution, it features tie-down reels for transport and a secure base that avoids contact with cable.

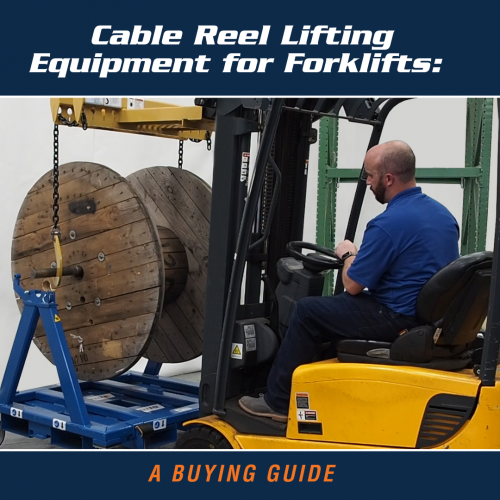

Overhead Reel Lifter (ORL) - The primary advantage of the Overhead Reel Lifter is right in the name: Ground-level electrical cable reels don’t provide sufficient clearance for some applications, and the ORL allows overhead lifting of up to 5,000 pounds. The keyhole slots on each beam enable quick adjustments for common reel sizes, while a storage tray houses the hook-and-chain assemblies when not in use.

Its safety chains feature spring-loaded clasps and slip hooks, which ensure engagement with the forks and distribute weight evenly. Chains can be adjusted to limit lateral tension. The ORL is a convenient option for lifting, transporting, and racking spools of up to 59 inches in diameter.

Reel Sherpa Cradle (RSC-5K) and Parallel Reel Payout (PRP) - Many operations use dedicated equipment for payout, which can greatly improve throughput in certain applications (for instance, electrical distribution or full-site electrical installation). The BHS Parallel Reel Payout, a forklift-movable system with free-spinning, multi-compartment reels, is one excellent option for this approach.

The PRP can be pre-loaded with product, and optional casters allow for free movement. But when utilizing payouts, operations still need a way to transport individual reels across the floor without risking damage.

The Reel Sherpa Cradle (RSC-5K) makes these types of location swaps significantly easier. Operators simply unhinge the built-in ramp, roll the reel onto the cradle, and secure it to the welded tie-down points. With a 5,000-pound capacity, the Reel Sherpa Cradle can be lifted with either pallet jacks or lift trucks, and the welded steel construction ensures durability.

To choose cable reel lifting equipment for forklifts, determine which option would provide the most flexibility in the warehouse or worksite. Most operations will need several attachments to accommodate different types of reels — the Overhead Reel Lifter might provide a solution for racking, for instance, but the Reel Sherpa Cradle might be a better option for quickly relocating reels in the warehouse or in the field.

Always choose attachments engineered with welded steel construction and pay close attention to optional product features. Reel handling equipment should provide years of reliable service while improving efficiency and ergonomics. At BHS, we work with our clients to ensure that every piece of equipment improves operational versatility and optimizes throughput.