We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Single Level Battery Extractors

An IIoT Battery Changing Solution for Up to 99 Forklift Batteries

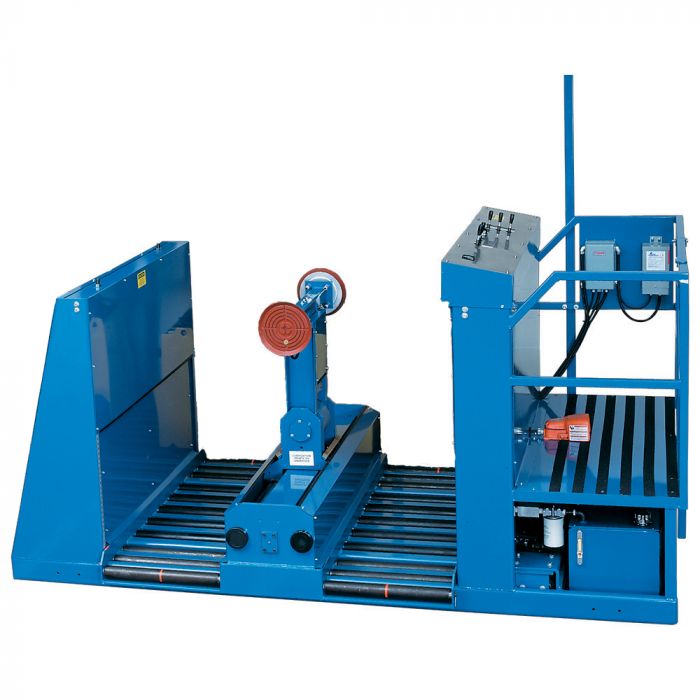

The BHS Single Level Battery Extractor (BE-SL) incorporates two pass-through roller beds and a powerful extractor arm to substantially reduce battery change-out time. For battery rooms that are not ready to install multi-tiered system stands, the BHS BE-SL provides consistently high levels of efficiency, ergonomic gains, and operator safety.

Digital integration provides Industrial Internet of Things (IIoT) features like condition-based and predictive maintanance, operator login controls, safety alerts, and usage tracking through the first-in-its-class BHS IIoT Portal.

This reliable forklift battery changer is ideal for fleets that use between 1 and 99 batteries. For higher-capacity battery handling needs, consider a Double, Triple, or Quad Stack Battery Extractor System — all of which offer the same IIoT solutions for greater uptime and service life.

BHS Operator Aboard Battery Extractors are highly customizable and can be constructed to meet any application’s unique specifications. To discuss the benefits of a Single Level Battery Extractor, speak with a member of our sales team.

Single Level Forklift Battery Changers for Tough Environments

Like the entire family of BHS Operator Aboard Battery Extractors, the BE-SL features a steel frame with extra-heavy duty construction. Industrial-grade steel components can easily support even the heaviest loads, and the BE-SL boasts a full lifting capacity of 10,000 lbs.

In addition to strength and dependability, Single Level Battery Extractors offer some of the fastest battery change-out times in the industry. Sensor arrays provide fully connected data collection and reporting through the cloud.

Call our sales department at 1.800.BHS.9500 to learn more or to find a dealer near you.

Features & Benefits

- Heavy-duty construction for added reliability

- Low-maintenance design plus condition-based and predictive maintenance capabilities with email notifications reduce downtime to the absolute minimum

- Digital support systems include the BHS IIoT Portal and touchscreen operator interface

- Through the BHS IIoT Portal, admins can authorize Portal users and asset Operators, adjust email notifications, turn on/off a 24-hour Daily Operator Checklist requirement, view historical usage data, access logged system alerts, and more from virtually any computer or mobile device

- Operator login prevents unauthorized access

- Proximity sensors on the unit dash prevent unauthorized changes to control systems

- No exposed components for added safety

- Durable powder coat finish resists both acid and scratches

- Manual control of hydraulics for easy operation

- Vacuum extraction reduces wear and tear on batteries

- Vacuum extractor arm adjustable for various reach requirements

- Non-proprietary hydraulic and electrical components lower replacement part costs

- Redesigned hydraulic system for increased flow capacities and consistent function speeds

- Quiet-running dual floor drive system provides positive traction on wet or dry surfaces

- BHS exclusive Non-Inter-Flow (NIF) hydraulic manifold system stabilizes the lift cylinders to ensure a level roller bed during load transfers

- Four lift cylinders, in combination with four-point equalization, assure smooth and level vertical movement of the roller bed when empty or loaded

- Five hydraulic-powered rollers per compartment provide a brake for safe, easy battery transfer

- Induction-type proximity switch disables floor drive to protect equipment when the extractor arm is outside the envelope of the compartment

|

BE-24-2-SL |

BE-36-2-SL |

BE-42-2-SL |

|

|

Travel Speed |

0 to 190 ft/min / 0 to 0.97 m/s |

0 to 190 ft/min / 0 to 0.97 m/s |

0 to 190 ft/min / 0 to 0.97 m/s |

|

Raise - Lower Speed |

0 to 10 ft/min / 0 to 0.05 m/s |

0 to 10 ft/min / 0 to 0.05 m/s |

0 to 10 ft/min / 0 to 0.05 m/s |

|

Powered Roller Speed |

0 to 37 ft/min / 0 to 0.19 m/s |

0 to 37 ft/min / 0 to 0.19 m/s |

0 to 37 ft/min / 0 to 0.19 m/s |

|

Arm Traverse Speed |

0 to 20 ft/min / 0 to 0.10 m/s |

0 to 20 ft/min / 0 to 0.10 m/s |

0 to 20 ft/min / 0 to 0.10 m/s |

|

Arm Rotation Time |

6 s to 8 s |

6 s to 8 s |

6 s to 8 s |

|

Draw Bar Pull / Vacuum (12” / 305 mm Round Cup) |

1,000 lb / 454 kg |

1,000 lb / 454 kg |

1,000 lb / 454 kg |

|

Draw Bar Pull Magnet* |

800 lb to 1,200 lb / 363 kg to 544 kg |

800 lb to 1,200 lb / 363 kg to 544 kg |

800 lb to 1,200 lb / 363 kg to 544 kg |

|

Vacuum Attach Time |

< 1 s |

< 1 s |

< 1 s |

|

Vacuum Release Time |

< 1 s |

< 1 s |

< 1 s |

|

Input Voltage |

240/480 V / 3 ph / 60Hz |

240/480 V / 3 ph / 60Hz |

240/480 V / 3 ph / 60Hz |

|

AC Current Draw |

20.2 / 10.1 A |

20.2 / 10.1 A |

20.2 / 10.1 A |

|

AC Current Draw w/ Electric Drive Option |

31.8 / 15.9 A |

31.8 / 15.9 A |

31.8 / 15.9 A |

|

Control Circuit Voltage |

120 V ac |

120 V ac |

120 V ac |

|

Hydraulic Power Unit |

5 hp / 3.73 kW |

5 hp / 3.73 kW |

5 hp / 3.73 kW |

|

Hydraulic Power Unit w/ Electric Drive Option |

8 hp / 5.97 kW |

8 hp / 5.97 kW |

8 hp / 5.97 kW |

|

Hydraulic Pump |

8 gal/min / 30 L/min |

8 gal/min / 30 L/min |

8 gal/min / 30 L/min |

|

Power Unit |

Hydraulic, Variable Displacement |

Hydraulic, Variable Displacement |

Hydraulic, Variable Displacement |

|

Operating Pressure |

1,500 psi / 103 bar |

1,500 psi / 103 bar |

1,500 psi / 103 bar |

|

Vacuum Pump |

1/3 hp / 0.25 kW |

1/3 hp / 0.25 kW |

1/3 hp / 0.25 kW |

|

Vacuum |

21” Hg / 711 mbar |

21” Hg / 711 mbar |

21” Hg / 711 mbar |

|

Full Load Capacity |

10,000 lb / 4535 kg |

10,000 lb / 4535 kg |

10,000 lb / 4535 kg |

|

Weight (Empty) |

5,800 lb / 2631 kg |

6,200 lb / 2812 kg |

7500 lb / 3402 kg |

|

Total Compartment Rollers / Powered |

11/5 |

11/5 |

11/5 |

|

Guide Track |

2” x 2.5” Angle / 51 mm x 64 mm |

2” x 2.5” Angle / 51 mm x 64 mm |

2” x 2.5” Angle / 51 mm x 64 mm |

|

Overall Dimensions (L x W x H) |

130” x 72” x 70” / 3302 mm x 1829 mm x 1778 mm |

154” x 72” x 70” / 3912 mm x 1829 mm x 1778 mm |

171” x 74” x 70” / 4343 mm x 1880 mm x 1778 mm |

|

Vacuum Arm Reach |

4.5” to 14” / 114 mm to 356 mm |

4.5” to 14” / 114 mm to 356 mm |

4.5” to 14” / 114 mm to 356 mm |

|

Vacuum Arm Reach (Hydraulic Extension) Truck Side |

9” to 23” / 229 mm to 584 mm |

9” to 23” / 229 mm to 584 mm |

9” to 23” / 229 mm to 584 mm |

|

Magnet Arm Reach (Hydraulic Extension) Truck Side |

14” to 22” / 355 mm to 559 mm |

14” to 22” / 355 mm to 559 mm |

14” to 22” / 355 mm to 559 mm |

|

Wheel Base |

95.75” / 2432 mm |

119.75” / 3042 mm |

134.5” / 3416 mm |

|

Drive Wheel Centerline |

53” / 1346 mm |

53” / 1346 mm |

53” / 1346 mm |

|

Battery Compartment Width |

24” / 610 mm |

36” / 914 mm |

42” / 1067 mm |

|

Maximum Battery Dimensions |

48” x 23” x 36” / 1219 mm x 584 mm x 914 mm |

48” x 35” x 36” / 1219 mm x 889 mm x 914 mm |

48” x 41” x 36” / 1219 mm x 1041 mm x 914 mm |

|

Minimum Battery Width (with vacuum / magnet) |

12” / 305 mm 6” / 152 mm |

12” / 305 mm 6” / 155 mm |

12” / 305 mm 6” / 155 mm |

|

Minimum Battery Length |

16.5” / 419 mm |

16.5” / 419 mm |

16.5” / 419 mm |

|

Minimum Battery Height |

17.75” / 451 mm |

17.75” / 451 mm |

17.75” / 451 mm |

|

Ground Clearance |

0.63” / 16 mm |

0.63” / 16 mm |

0.63” / 16 mm |

|

Roller Height |

6.5” Min / 26.5" Max 165 mm Min / 673 mm Max |

6.5” Min / 26.5" Max 165 mm Min / 673 mm Max |

6.5” Min / 26.5" Max 165 mm Min / 673 mm Max |

Note: Specifications may vary ± 5% because of temperature, floor considerations, and operator efficiency. Values represented under normal operating conditions.

* Varies with battery case thickness and condition.

Video Resources

Operator Aboard Battery Extractors from BHS

IIoT Functionality on Operator Aboard Battery Extractors

BE Option: Fleet Tracker

Battery Extractor Options – Part 1

Battery Extractor Options – Part 2

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.