We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Fleet Tracker®

Fleet Tracker® is a cloud-based, IIoT-powered fleet management system for electric forklifts and their lead-acid batteries. This system drives operational savings through extended battery life, faster change-outs, right-sized fleets, and streamlined battery room processes.

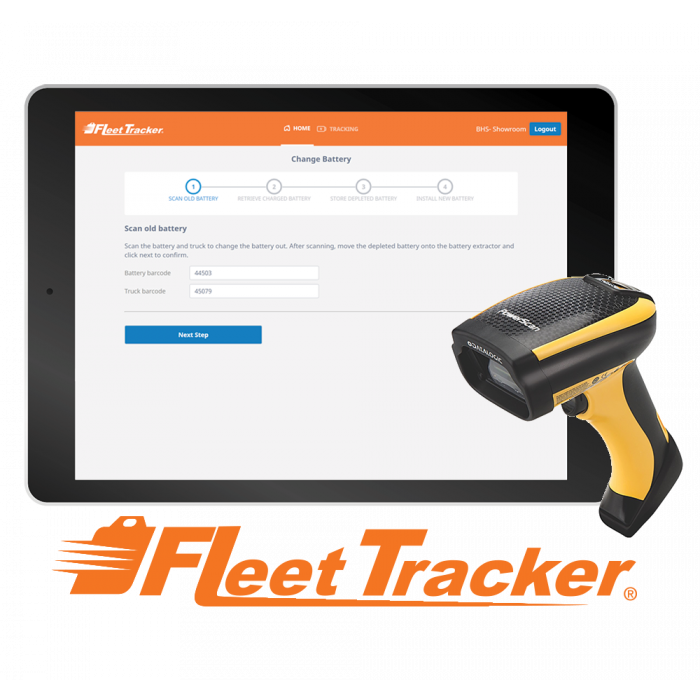

Managers and battery room operators interact with Fleet Tracker through a Web Portal and an Operator Portal, respectively. Users access the Operator Portal through an included touchscreen tablet mounted directly on the battery extractor. Fleet Tracker also comes with a lightweight scanner and carriage-mounted holster. The system identifies charged batteries using a First In, First Out rotation. Quick barcode scans with the included lightweight scanner update the system with the location and condition of every battery, rack, and truck in the fleet.

Maintenance prompts ensure that batteries are watered, washed, and equalized on schedule, extending their working lives. The system guides the operator to a charged battery, speeding up battery changes, and a Stage-on-Extractor mode can even reduce change-outs to a single minute per truck.

Managers can log into the Fleet Tracker Web Portal from anywhere with an internet connection. There, they access a snapshot of fleet health with color-coded condition monitoring for all assets. Digging into the data allows managers to create detailed reports, helping to right-size the fleet with frontline usage statistics.

Fleet Tracker is ideal for any operation that uses Automatic Transfer Carriages, Mobile Battery Extractors, or Operator Aboard Battery Extractors, including BHS competitors, and supports multiple facilities and battery rooms within a single system. To learn more about IIoT battery management, call the BHS sales team at 1.800.BHS.9500.

Features & Benefits

- Industrial Internet of Things (IIoT) technology tracks and analyzes battery room operations to help managers reduce maintenance costs, increase productivity, and improve profitability

- Hardware includes touchscreen tablet, lightweight scanner with holster, and hardware for mounting on the battery extractor carriage

- Software includes the Operator Portal, available through the included tablet; the Web Portal, available with log-in credentials from any internet-connected device; and cloud-based Fleet Tracker system

- Detailed reporting and analytics platform provides real-time data for right-sizing the fleet and maintaining optimal productivity

- First In, First Out battery tracking maintains proper battery rotation, maximizing battery life

- Operator Portal guides users directly to available batteries, reducing change-out time considerably

- Stage-to-Stand and Stage-to-Extractor modes can cut change-out time even more dramatically, even down to a single minute

- Maintenance tracking with adjustable prompts keep batteries operating at peak efficiency

- System prompts operators when it's time for washing, watering, and equalizing batteries

- Sequential watering and other built-in efficiencies improve maintenance efficiency

- Barcode-based system tracks all fleet assets, including batteries, stands, and trucks

- Scanning a unit instantly updates asset location and condition in the cloud

- Tracks assets across multiple battery rooms, battery extractor systems, and facility locations, simplifying asset transfers between each

- Skipping the system's chosen battery automatically de-commissions the unit for later maintenance while immediately recommending the next ready battery

- De-commissions and re-commissions batteries and/or trucks with a single scan

- Web Portal dashboard shows all fleet assets with color-coded condition indicators, providing a full picture of fleet health at a glance

- Easy-to-read bar graphs provide more granular data about productivity, asset health, usage, and more

- Managers can generate detailed reports to inform operational decisions

- Web Portal Admins can set and change user permissions for each system

- Comprehensive IIoT system for electric forklift fleet management across facilities

California Residents: WARNING: This product contains chemicals known to the State of California to cause cancer and/or reproductive harm, and birth defects or other reproductive harm. Learn more here.