We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Understanding the Forklift Stability Triangle

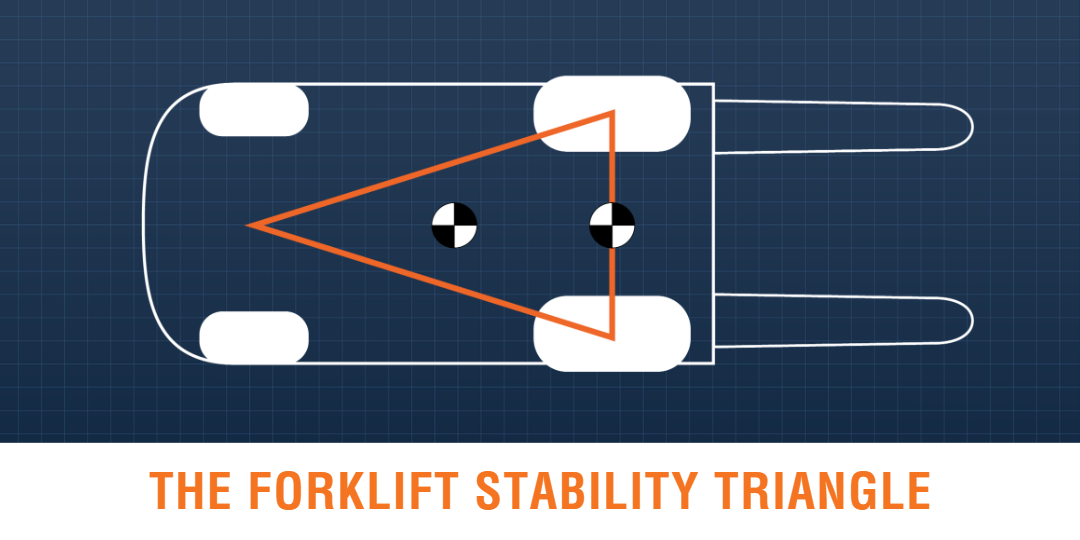

The forklift stability triangle is a fundamental concept that operators of counterbalanced lift trucks must understand. In order to maintain longitudinal, lateral, and dynamic stability, operators must be able to locate the center of gravity of a loaded truck and ensure that it falls within this imaginary triangle that spans the front axle to the center of the steer axle.

What is the stability triangle?

Most counterbalanced forklifts have a three-point suspension system, meaning that the truck is supported at the two front wheels and the center of the steer axle. If you imagine all three points connected into a triangle, this is the forklift's stability triangle. When the lift truck's center of gravity falls within the perimeter of this triangle, a load is safe to carry.

Now, when there is no load present, the lift truck's center of gravity is firmly inside the triangle. Because there is no load, the center of gravity is nearly in the center of the forklift's counterbalance. As you add weight to the forks, the center of gravity shifts closer to the front axle. Once the center of gravity reaches the front axle, it is at the edge of the stability triangle, and the load becomes unsafe to carry.

Longitudinal stability isn't the only concern for lift truck operators.

There is also lateral stability to consider. A forklift can overturn sideways if the center of gravity leaves the stability triangle on either of the two sides. For this reason, it is important to keep the center of gravity as near as possible to the center of the forks (remembering that the center of gravity may not be the geometric center if the load has irregular weight distribution).

Furthermore, operators must consider dynamic stability. This is the idea that a load can shift due to sudden stops, starts, turns, or tilts. Because of these possibilities, operators should be careful to keep the center of gravity firmly within the stability triangle.

For instance, if a heavy load brings the center of gravity all the way to the front axle — the theoretical edge of the stability triangle — sudden braking could shift the load forward and out of the triangle altogether. That slight nudge could cause the rear wheels to raise or tip the lift truck entirely. What seemed like a stable load became an unstable one due to dynamic forces.

Now let's add the third dimension.

The traditional model of the forklift stability triangle is useful, but it leaves out one important thing: three-dimensional space. In actual fact, the stability triangle is a pyramid.

As a load moves upward, it shifts the truck's center of gravity forward. A safe load at 4 inches off the ground may tip the forklift at 4 feet up. That's why OSHA training documents instruct operators to always "carry the load at the lowest position possible, 4 to 6 inches from the ground."

Luckily, there are plenty of other ways to improve forklift stability.

Refrain from accelerating, braking, or turning suddenly. These actions shift the center of gravity, increasing the chance of tipovers. Never turn while on a grade or ramp; this greatly increases the odds of a lateral rollover.

When operators are arranging a load, they should be aware of hazards, such as tipover, loss of steering control (due to raised rear wheels), falling loads, and collisions. Operators should watch out for the following red flags:

- Loads that exceed the capacity stated on the data plate.

- Unstable, off-center loads.

- Raised rear wheels — this is an indication that the truck is overloaded.

- Items with a high center of gravity — keep the load as low as possible.

No forklift operator can predict every possible event.

However, by keeping loads well within the bounds of the stability triangle, they can keep their truck steady even when unforeseen conditions require sudden braking, turning, or accelerating. Not bad for an imaginary triangle!

References

"29 CFR 1910.178 Appendix A" OSHA. Occupational Safety & Health Administration. 1 Dec. 1998. Web. 18 Apr. 2018.

"Powered Industrial Forklifts." OSHA. Occupational Safety & Health Administration. n.d. Web. 18 Apr. 2018.