We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Last Mile Logistics: A Guide for Distribution Center Operators

If you operate a distribution center or any other business in the logistics space, you’ve probably heard quite a bit about last mile logistics over the past several years.

|

Controlling the last mile of shipping can yield enormous benefits for organizations of all sizes, but that’s easier said than done: The problems with last mile logistics were exposed at scale during the COVID-19 pandemic lockdowns, and they’ve grown significantly since then.

In this article, we’ll provide a brief introduction to the core problems of last mile delivery — and explain how an appropriately outfitted distribution center can keep up with the trends.

What Is Last Mile Delivery in Logistics?

The journey of a product can be divided and subdivided into dozens of steps, depending on the product and the customer. Ultimately, though, every product eventually needs to reach the customer. “Last mile delivery” refers to that final step of the process: when the product is sent out to the buyer.

This is a critical opportunity for optimization. In 2024, both businesses and consumers expect quick, cost-effective deliveries, and distribution centers that meet that expectation can keep customers satisfied.

That’s no small feat; in one survey, 62% of consumers said that delivery speeds influence their purchasing decisions, and 30% expected same-day delivery. And while the business-to-business (B2B) sphere can be slightly more forgiving, efficiency is still crucial. About 65% of B2B companies offer eCommerce capabilities, and shipping speed is a key differentiator.

Why Is Last Mile Delivery So Expensive?

Unfortunately, the last mile of the shipping process requires a great deal of work. Human workers need to load vehicles and drive them to their final destinations.

Those personnel need to be hired, trained, and re-trained — and replaced, given that turnover rates are extraordinarily high.

High shipping costs can be driven by a number of other factors:

- The last mile is notoriously unpredictable. A sudden surge of traffic, for example, could have an outsized impact on a small DC’s output for the day.

- Product loss is much more likely during the last mile of delivery due to theft, mishandling, and accidents.

- Fuel consumption, delivery time slots, and other factors may add to the complexity of delivery for a given order.

- The process of loading products onto carrier vehicles can be time consuming (and expensive).

By one estimate, the final mile of delivery accounts for as much as 53% of the total cost of shipping.

How Can Distribution Centers Support Last Mile Delivery?

Optimization is absolutely essential, even if it’s not necessarily easy. Route planning tools can use location-specific algorithms to send drivers where they need to be — but for distribution centers, there’s a much better place to start.

For DCs, the key is physical flexibility. Centers must be ready to adapt at a moment’s notice. That begins with the “first foot of the last mile:” the loading process.

Docks aren’t just for semi-trailers anymore. Sprinter and cargo vans play an important role in modern logistics, and DCs must be prepared to handle an extensive variety of parcel delivery vehicles without losing a step.

Back in 2020, we wrote about the advantages of establishing last mile delivery ramps at loading docks. A carrier-ready ramp configuration limits some of the major costs that DCs incur during the last mile:

- Personnel can load products quickly, regardless of the vehicle type.

- An ergonomic loading process promotes staff engagement and retention.

- A more versatile loading dock can handle sudden increases in demand or adapt to other conditions (such as inclement weather or traffic congestion).

Loading Ramps for Last Mile Delivery Material Handling

BHS, Inc. manufactures hydraulic last mile delivery ramps, which can serve vehicles of any size without requiring your staff to navigate dock-to-ground ramps or steps with every order.

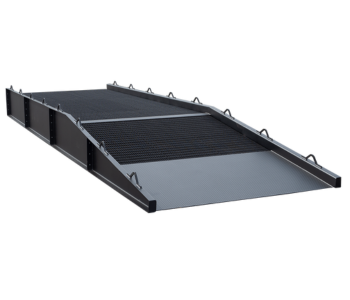

Products to Consider: Loading Dock Ramp (LDR)

The Loading Dock Ramp (LDR) features a four-section, modular design that brings cargo vans up to dock height, increasing outbound throughput while limiting ergonomic risks.

The standard LDR allows delivery vans to back up to dock doors for loading. Steel curbs keep the vehicle safely on the platform, and the 24" elevation adds dock functionality without requiring new construction or remodeling.

While the LDR is designed for cargo vans and standard-height docks, custom ramps are available on request to support any combination of dock placement and vehicle height.

Products to Consider: Modular Loading Dock Platform (MLDP)

The Modular Loading Dock Platform pairs a forklift ramp with trailer-height loading platform via a bolt-together steel assembly. It allows a single dock door to be converted into multiple trailer positions, and it can be used to support shipping capacity on demand.

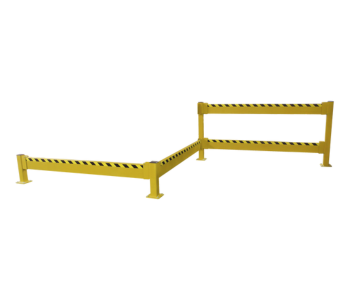

The BHS custom engineering team designs each Modular Loading Dock Platform to match the customer’s unique needs. Your dock platform could include multiple loading positions, as well as any platform size, weight capacity, or loading height. We also integrate additional features, from enclosures to dock levelers to Safety Barriers and Guardrails.

Prepare for the Future of Last Mile Delivery

Within the next several decades, we expect to see two trends revolutionize last mile delivery logistics: autonomous delivery vehicles (ADVs) and sustainable, eco-friendly vehicles.

Autonomous vehicles will have obvious, immediate benefits for businesses (which is why eCommerce giant Amazon is already investing heavily in the technology). Of course, full autonomy will require significant advances in artificial intelligence — but electric vehicles (EVs) are already on the roads. Distribution centers can position themselves for EVs by installing charging stations that meet the National Electric Code (NEC) Article 625 standard.

Custom Material Handling Solutions for Last Mile Delivery

At BHS, we help distribution centers create robust material handling strategies for last mile delivery. That includes strategies for the future of logistics.

Whether you need to design a docking solution for a specific application or find material handling equipment that supports your operation’s unique workflow, we’re ready to get started. Call 1.800.247.9500 to speak to our sales team or to find a local dealer.