We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

OSHA Standards for Scissor Lift Safety in Elevating Work Platforms

Scissor lifts are frequently used as work platforms — and anytime you’re asking workers to use heavy equipment, you need to think about compliance with relevant standards from the Occupational Safety and Health Administration (OSHA).

|

But contrary to popular misconception, scissor lifts do not fall under OSHA’s definition of “aerial lifts.” This may seem confusing; after all, scissor lifts are designed to lift workers vertically. If that’s not an “aerial lift,” what is an aerial lift?

In this article, we’ll explain the basics of OSHA’s terminology and identify standards that apply to scissor lift work platforms. However, this article should not be interpreted as legal advice. Always consult with a qualified safety professional to address safety concerns and before making any changes to your operation’s established work practices.

According to OSHA, Scissor Lifts Are Scaffolds

OSHA defines aerial lifts as “any vehicle-mounted device used to elevate personnel.” But scissor lifts are typically fixed, not vehicle-mounted, so they don’t qualify as aerial lifts.

|

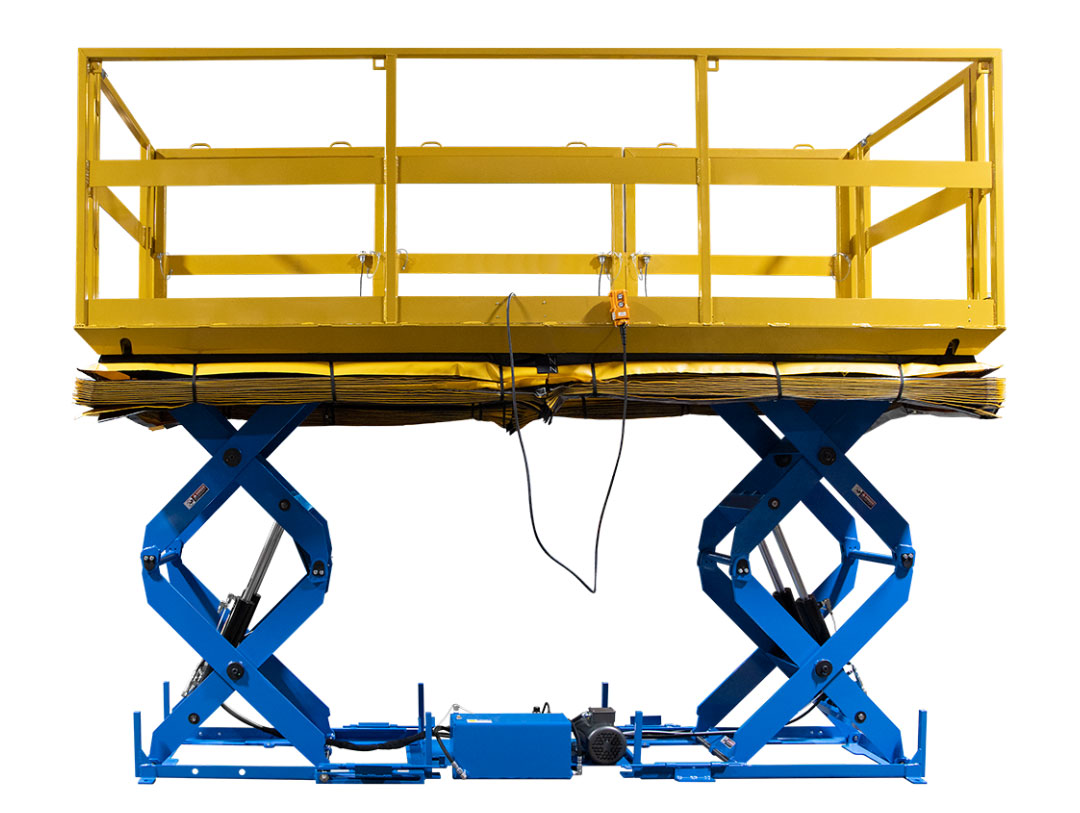

| Custom Aerial Work Platform from BHS, Inc. |

More specifically, OSHA defers to the American National Standards Institute (ANSI) A92.2-1969, which defines aerial lifts as: "extensible boom platforms," "aerial ladders," "articulating boom platforms," "vertical towers," and "a combination of any of the above." That doesn’t apply to most scissor lifts.

In a 2000 interpretation letter, OSHA director Russell B. Swanson wrote:

There has been some confusion as to which OSHA standards apply to the use of scissor lifts. The aerial lift requirements (§1926.453) incorporate by reference the definition of aerial lifts used in the American National Standards Institute (ANSI) A92.2-1969 standard.

Therefore, the requirements in §1926.453 apply to equipment identified in that 1969 ANSI consensus standard as aerial lifts.

Swanson notes that while there aren't specific OSHA provisions that address scissor lifts, they do meet the definition of a scaffold. That means that OSHA standards for scaffolds are applicable, though some of those standards are specific to suspended scaffolds; scissor lifts are supported scaffolds.

OSHA Scissor Lift Requirements: 1926.451

OSHA general standards for scissor lifts can be found under §1926.451, “Scaffolds.” These standards are fairly involved, and many apply to the construction of the scaffold (or, in this case, the manufacturing specifications of the scissor lift).

While 1926.451 contains technical specifications, other standards may also apply depending on the design of the equipment and the industry of the employer. Key OSHA standards for scissor lifts include:

- 27 – Scaffolds and rope descent systems.

- 28(b)(12) – Duty to have fall protection and falling object protection.

- 29(b) (Note) – Fall protection systems and falling object protection-criteria and practices.

|

|

Platform railings and safety harness attachment |

Scissor lifts standards for the construction industry:

- 20(b) – Accident prevention responsibilities.

- 21 – Safety training and education.

- 451 – General requirements.

- 452(w) – Additional requirements applicable to specific types of scaffolds - mobile scaffolds.

- 454 – Training requirements.

Standards for shipyards:

- 71 – Scaffolds or Staging

We’ll explain some of the specific requirements of those standards in the next section. However, to ensure full OSHA compliance, you should review relevant standards in their entirety.

OSHA Training Requirements for Scissor Lift Work Platforms

OSHA’s 29 CFR 1926.454(a) requires that employees are trained by a “qualified person” to recognize the hazards associated with the type of scaffold being used (in this case, a supported scaffold). Employees must understand how to control or minimize those hazards.

Per OSHA, training must be provided by a “qualified person" who either “possesses a recognized degree, certificate, or professional standing,” or “by extensive knowledge, training, and experience has successfully demonstrated the ability to solve or resolve problems relating to the subject matter, the work, or the project.”

|

| Skid tape offers maximum slip resistance in most work environments |

Training should include instruction regarding:

- Falling object hazards

- Electrical hazards.

- Proper use of scaffold.

- Handling of materials.

1926.451(g), “Fall Protection,” is especially pertinent. Per that standard, employers should train workers to:

- Stay on the work platform — don’t stand on the guardrails or any other part of the lift.

- Make sure that a guardrail system is in place before working on the scissor lift.

- Keep work within reach to avoid leaning and to reduce falling object hazards.

- Report any equipment defects or maintenance needs.

The employer has a responsibility to ensure that workers are trained — and, if necessary, retrained when the nature of the hazard changes.

To that end, have a training policy that includes regular proficiency checks. Only trained workers are allowed to use scissor lifts, and employers must provide appropriate personal protective equipment (PPE) for these individuals.

PPE requirements must match the hazard, but guardrails are generally sufficient for fall protection. Personal fall arrest systems are not required in most circumstances.

Related: What Training Does OSHA Require? An OSHA Training FAQ

Prioritizing Scissor Lift Safety on the Worksite

Employers must also ensure that scissor lifts are appropriately stabilized and positioned. The lifts should meet relevant ANSI standards, which may include ANSI A92.3-2006 (Manually Propelled Elevating Aerial Platforms) and A92.6-2006 (Self-Propelled Elevating Work Platforms).

|

| Sensors ensure gates are closed before the unit is operational. |

Some general tips for deploying scissor lifts:

- Choose work locations with firm, level surfaces. Minimize hazards surrounding the platform (such as drop-offs, holes, or debris). If using the platform on a slope, ensure that the slope is within the manufacturer’s specifications.

- Ensure that safety systems designed to stop a collapse are maintained. Do not bypass safety systems.

- Ensure that the weight on the work platform does not exceed the manufacturer’s load rating.

- Never use equipment other than the scissor mechanism to raise the work platform.

- Never move scissor lifts while the lift is in an elevated position.

- Control traffic near the scissor lift. Make sure the lift is not struck by other equipment.

- Only use scissor lifts outdoors when the weather conditions are appropriate. Pay attention to wind — high wind speeds can make lifts unstable.

- Test and inspect the controls and components before each use. This includes the controls for the scissor lift, the brakes, and the guardrail systems.

Related: OSHA Standards for Industrial Work Platforms Mounted on Forklifts

Follow Manufacturer Instructions When Employing Scissor Lifts

According to OSHA, most injuries and fatalities involving scissor lifts were a result of employers failing to properly address fall protection, stabilization, and positioning.

As is always the case with heavy equipment, it’s important to follow the manufacturer’s instructions. Pay close attention to available safety controls, maximum lifting weight/height, voltage, and other specifications when making your purchase — and give workers access to those materials to ensure that they can use the equipment safely.

|

| Optional accordion skirt guarding protects workers at ground level |

When Purchasing Scissor Lifts, Prioritize Safety

OSHA provides additional resources for ensuring compliance when using scissor lifts and other types of scaffolds. The Scissor Lift eTool provides basic guidance (though we’ve addressed most of that guidance in this article). The General Scaffolding eTool includes additional info on guardrails, guardrail materials, and scaffold work areas.

Remember, safety begins with purchasing. BHS provides custom scissor lifts with exceptional safety controls and high-quality materials — and if you’re ready to improve productivity while optimizing safety, we’re here to help. Call 1.800.BHS.9500 to speak with a member of our sales team or submit an info request online.