We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Loading Dock Ramps: A Buying Guide for Warehouse Operators

To improve warehouse efficiency, start by identifying your current bottlenecks. These are the places and processes that slow down your whole operation — and one of the most likely culprits is your loading dock.

Docks only contain so many bays, which means the number of trucks you can load or unload is limited. Demand is not limited. It surges during peak season (and sometimes seemingly at random). A loading dock that’s more than sufficient in March may cause huge delays in December, or even for an odd week in June.

Loading dock ramps are the solution. They provide quick access to trailers, docks and the ground without the cost and complexity of building new bays onto your dock.

Of course, flexible dock capacity is just one of the reasons you might shop for a loading dock ramp. They also solve a lot of other logistics challenges, including:

- Accessing last-mile delivery vehicles from standard-height docks

- Supporting forklift traffic from the dock to the ground and back

- Creating pedestrian travel paths between levels

- Building temporary loading/unloading areas

- Adding new dock positions without traditional construction

As you might guess from the diversity of this list, there’s more than one type of dock ramp, and they’re all designed for different purposes. This buyer’s guide to loading dock ramps will help you choose the best solution for your facility, starting with an introduction to the four major categories of dock ramps.

See all Dock Equipment from BHS, Inc.

|

| Dock Ramp |

4 Types of Loading Dock Ramps

A dock ramp is any inclined surface that connects a dock to the ground, the ground to a trailer (or van or train car), or a vehicle to the dock. Specifically, most logistics challenges will be solved with one of four types of loading dock ramps:

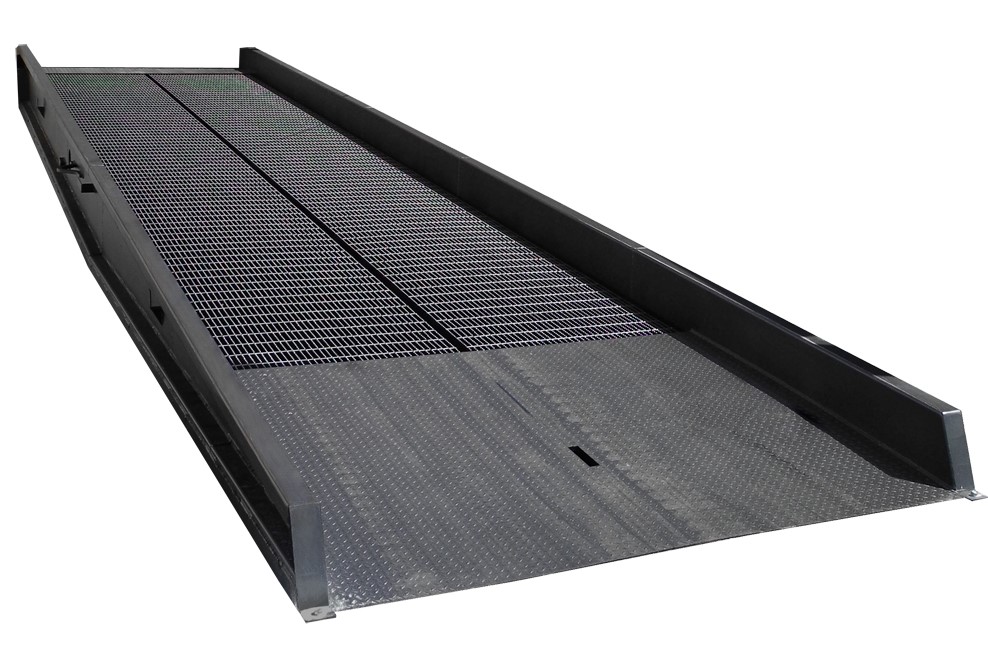

- Stationary Dock Ramps - These ramps are more-or-less permanent additions to your loading dock, where they provide passage between the dock and the ground. You might also find them described, accurately, as “dock-to-ground ramps.”

Explore Dock Ramps from BHS, Inc.

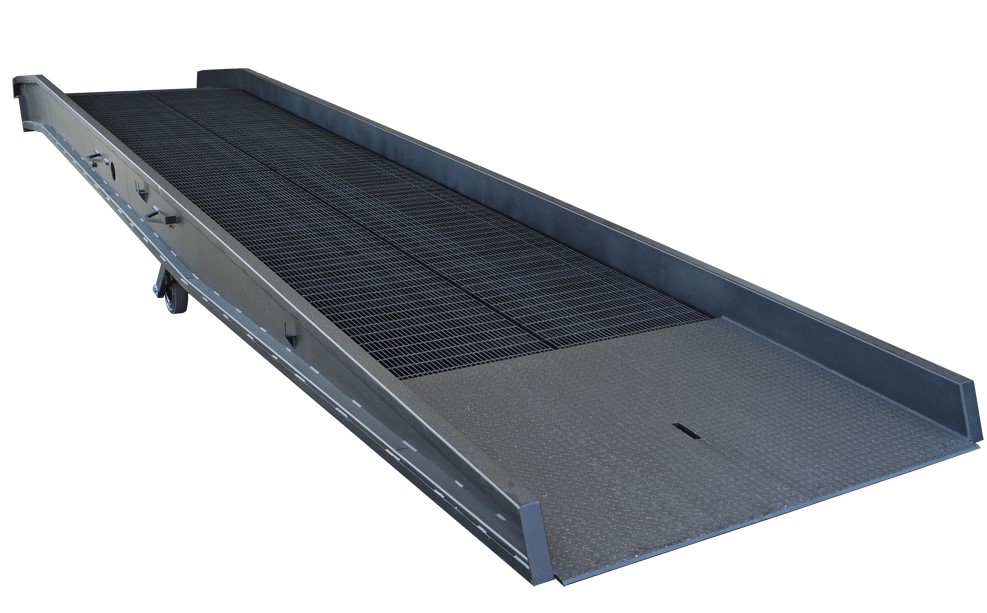

- Mobile Yard Ramps - Portable dock ramps are fixed with wheels on one end. They’re designed to be carried to a trailer or train car via lift truck or tugger. Once in place, they provide direct access to storage containers from ground level.

Learn about Yard Ramps from BHS, Inc.

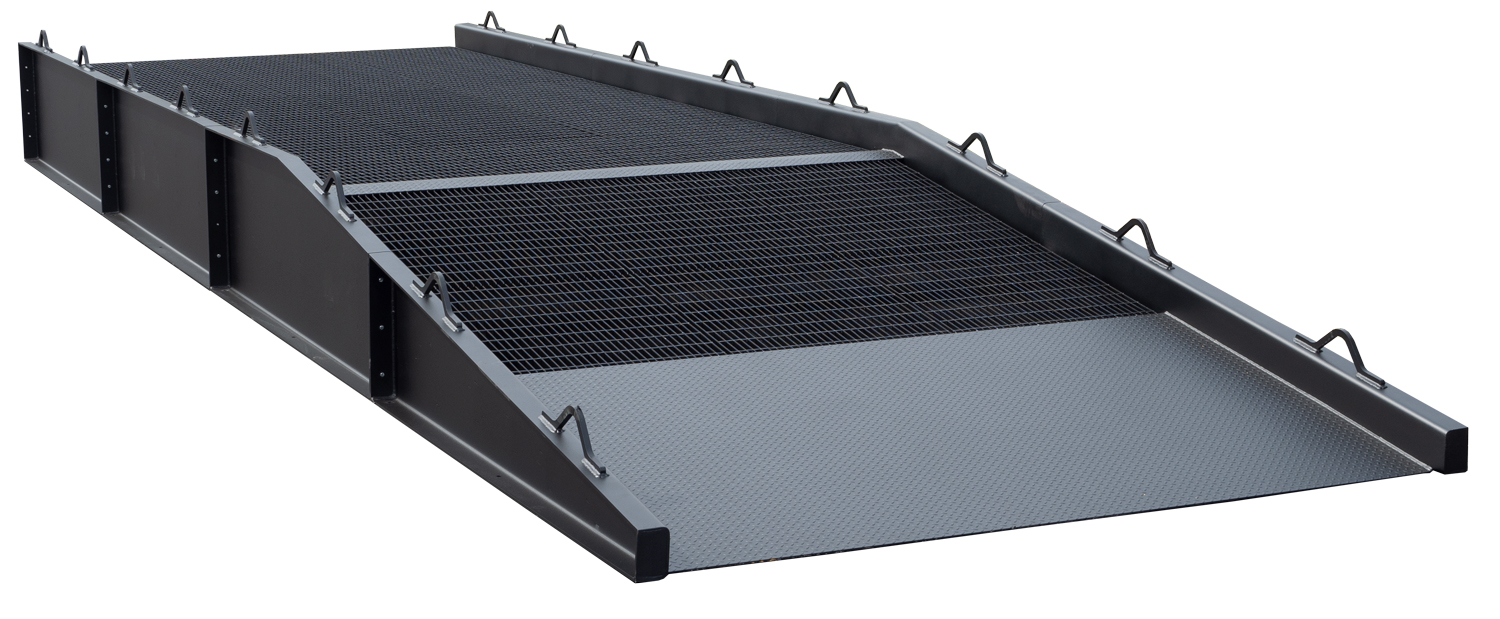

- Modular Loading Dock Platforms - This is a ramp with an integrated work platform at the top. These free-standing structures are ideal for temporary logistics installations, where they act as miniature loading docks in their own right.

View Modular Loading Dock Platforms from BHS, Inc.

- Loading Dock Ramps for Delivery Vans - Loading docks are mostly built for tractor trailers, which means they’re too high for last-mile delivery vehicles. The solution is a Loading Dock Ramp that elevates delivery vehicles to a standard dock height, providing direct access to your facility (and improving both safety and efficiency for last-mile load-outs.)

Get to know Loading Dock Ramps from BHS, Inc.

|

| Yard Ramps |

How can you tell which of these four types of dock ramps is best for your situation? Start your research by answering the following five questions.

Choosing a Loading Dock Ramp: 5 Questions to Help You Decide

1. What challenge is the loading dock ramp designed to solve?

Loading dock ramps are tools. As in any other task, you’ll get the best results when you choose the right tool for the job. The first question to answer, then, is simple: What do you need your loading dock ramp to do?

- If you need to create a permanent traffic lane — for forklifts or pedestrians — choose a stationary Dock Ramp.

- To unload trucks away from the traditional dock, purchase a mobile Yard Ramp.

- For temporary loading/unloading facilities, or to expand capacity in your yard, Modular Loading Dock Platforms might be your best bet.

- To load last-mile delivery vehicles at your existing dock, install an elevating Loading Dock Ramp.

If you can’t find a loading dock ramp that fits your need, contact BHS to discuss a custom solution. We can alter any of our existing models, or engineer a whole new design, to match any use case. Call us at 1.800.247.9500 to start the conversation.

2. What kind of traffic will the ramp support?

Most loading dock ramps are designed for forklifts — but, as we’ve mentioned, some carry delivery vehicles or pedestrians instead.

For vehicle traffic, look for loading dock ramps that include high steel curbs on either side. This safety feature helps to reduce the risk of roll-off. If pedestrians will use your dock ramp, choose a model with OSHA-compliant handrails. For combined use, choose a model with both curbs and handrails.

Read more: OSHA Guidelines for Forklift Traffic on Dock Ramps and Yard Ramps

3. How heavy are the loads you handle?

It’s essential to choose a dock ramp that can safely handle any weight you might need. Factor in the weight of vehicles and the heaviest load they might carry. All BHS dock ramps are made of steel and constructed for heavy-duty usage, and we can create custom models to support virtually any load. That said, here are the maximum capacities for standard ramps from BHS, Inc.:

|

| Loading Dock Ramp |

- Dock Ramps: Up to 40,000 pounds (18,144 kilograms)

- Yard Ramps: Up to 25,000 pounds (11,340 kilograms)

- Loading Dock Ramps: Up to 25,000 pounds (11,340 kilograms)

- Modular Loading Dock Platforms (Varies to match use case)

Lighter-capacity models are also available in standard BHS models. For example, Dock Ramps are also available with capacities of 16,000 or 20,000 pounds (7,258 or 9,072 kilograms). And, of course, custom ramps can fit any requirement.

4. How much space do you have for a ramp?

Consider the space you have for a ramp’s whole length, and choose a model that provides plenty of clearance for approach. But be aware that loading dock ramps can never be too short.

According to Occupational Safety and Health (OSHA) standard 1926.451(e)(5)(ii), ramps must slope with a maximum angle of 20 degrees above the horizontal. Depending on the height of your dock, that requirement places limits on just how short a ramp should be — and you definitely want a low, steady angle for safe traffic up and down the ramp.

While all BHS ramps provide this safe, OSHA-compliant slope, they’re also available in lengths from 20 feet (6.096 meters) for a short stationary Dock Ramp to 36 feet (10.973 meters) for a mobile Yard Ramp. Custom lengths are also available, as long as they support an angle that’s safe for traffic.

|

| Modular Loading Dock Platform |

5. What material is best for your loading dock ramp?

In virtually every case, dock ramps should be made primarily of heavy steel, a material that’s strong enough to safely support heavy loads. However, some specialty ramps may incorporate wood decking (for use with metal-treaded vehicles, for instance) or other materials.

For most standard vehicle traffic, including vans and forklifts, choose an all-steel ramp, complete with steel decking. Just be sure the ramp includes features that improve traction — as well as a solid steel approach plate designed to absorb the initial impact of heavy vehicles.

All BHS ramps incorporate such an approach plate before transitioning to an open steel grating, which provides traction and durability at once.

Read more: Installing Ramps With Built-In Safety Features to Prevent Serious Accidents

Dock Safety Beyond the Ramp

With these questions answered, you know what to look for in a loading dock ramp. (And if you still have more questions, don’t hesitate to contact BHS at 1.800.247.9500.) While you’re reconfiguring your dock with a ramp, however, you might also consider additional safety equipment. For example, you can improve dock safety with:

- Structural Barrier Rails - Originally designed to protect aisles and equipment from forklift strikes, this heavy-duty railing system can also help prevent roll-offs at the dock.

- Structural Bollards - Protect the edges of ramps and other dock equipment with a few well-placed steel bollards, available in heights of 24 inches (609.6 millimeters), 36 inches (914.4 millimeters), or 42 inches (1,066.8 millimeters).

- Powered Dock Gates - This high-visibility gate lifts or drops at the press of a button. When in place, it serves as a visual deterrent for forklift operators, and withstands forces of 10,000 pounds at 4 miles per hour to prevent dangerous accidents.

Explore the full collection of BHS Dock Equipment here.

For help deciding which dock ramps and barriers will provide the most benefit for your use case, contact the BHS sales team at 1.800.247.9500 today.