We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

How Tilt Tables Improve Ergonomics in Manufacturing

Every product has its unique manufacturing challenges. When the things you build are big, however, access to work itself becomes the bottleneck. How can workers safely assemble components at either end of an industrial mold, appliance, or sofa, when their reach only extends a few feet?

This access issue isn’t just a question of productivity. Poor access increases the risk of musculoskeletal disorders, work-related injuries caused by repetitive motion and awkward movements — such as bending, stretching, and reaching.

Ergonomics is the study of matching work to the worker, in the hopes of preventing musculoskeletal disorders and other health risks. As you design assembly stations for your manufacturing line, ergonomics is a crucial concern. As an added bonus, good ergonomic design tends to improve productivity while also reducing injury risk.

So what’s the best way to solve the access problem if you manufacture molds, dyes, heavy equipment, furniture, appliances, or other large, awkward products? You essentially have two options:

- You can bring the worker to the work, providing scaffolds, mezzanines, Lift Table Ladders, or even adjustable Aerial Work Platforms that lift and lower employees as needed.

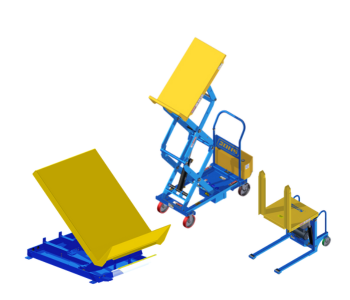

- You can bring the work to the worker with Scissor Lift Tables or, for even more access, hydraulic Tilt Tables.

If you need access to multiple sides of a large, heavy product, Tilt Tables are the ideal solution. Here’s why, along with an example of a custom Tilt Table at a heavy manufacturing facility.

What Are Tilt Tables, and How Do They Improve Ergonomics in Manufacturing?

Tilt Tables are work-positioning machines that lift one side of an L-shaped platform, repositioning contents up to 90 degrees (or more, in some cases). They don’t just elevate objects, like a Lift Table; they turn them, providing new angles of access on demand.

Assemblers use smaller Tilt Tables for quick, ergonomic access to the contents of boxes. As contents are emptied, users typically have to reach further into the box. Tilt Tables instead bring these contents closer to the user, saving time and reducing strain.

Larger Tilt Tables provide stress-free access to the full length of large products. They’re often designed to integrate into broader assembly lines, rotating flush with roller conveyors or safely depositing products onto trucks or pallets.

This work positioning greatly improves ergonomics in (at least) three ways:

- Tilt Tables eliminate the need to climb, stretch, or otherwise contort the body to reach tops and sides of large products.

- They rotate large, heavy objects onto their sides, replacing manual repositioning and all its attendant risks.

- As part of an integrated material handling system, Tilt Tables safely position products for any material handling equipment and/or later assembly stations.

These advantages explain why the Occupational Safety and Health Administration recommends using “a device to lift and reposition heavy objects to limit force exertion” in its ergonomics guidelines.

Of course, to get the most benefit from a Tilt Table, you often need custom design, manufacturing, and material handling integration services. Here’s an example of what such a custom Tilt Table can accomplish on a heavy manufacturing line.

A Custom Tilt Table for Truck-Bed Assembly

Knapheide Manufacturing Co. builds industry-leading utility truck beds; if you run a fleet of work trucks, odds are you’re using Knapheide’s products.

But to build truck bed side packs, Knapheide’s employees need access to all sides of a large, heavy product — including the underside. When their previous, ad-hoc solution reached the end of its service life, the Knapheide team turned to BHS, Inc. to produce a heavy-duty, custom Tilt Table for day-to-day work positioning on the side pack assembly line.

Engineers at BHS designed a 20-foot-long Tilt Table, complete with steel L-brackets that fold into the floor of the unit, effectively granting ergonomic access to the underside of the product while integrating into the line’s roller conveyor system.

Learn more about this custom Tilt Table product in our case study, “BHS, Inc. Provides Custom Tilt Table for a Knapheide Manufacturing Line.”

To discuss Tilt Tables that can improve ergonomics on your manufacturing line, contact the BHS sales team at 1.800.247.9500 today.