We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Forklift/Pedestrian Safety at the Dock

In 2019, the Bureau of Labor Statistics (BLS) looked through the data on forklift accidents at work. They discovered that forklift operators aren’t the only ones at risk. Of the 9,050 forklift-related injuries BLS tallied in 2017, 1,850 involved pedestrians. That made pedestrians the injured parties in more than 20 percent of these cases. Even worse, pedestrians injured by forklifts required more days off than workers injured in other forklift-related cases.

These statistics won’t be a surprise to anyone who works around a loading dock. It’s hard to separate pedestrians and forklifts at a dock. There are lots of blind corners. When things get busy, docks can become chaotic.

According to the National Institute for Occupational Safety and Health (NIOSH), the best way to control injury risks at work is to remove or replace the hazard. That’s not an option at a busy loading dock. The next-best approach, however, is to install engineering controls — equipment or modifications that isolate at-risk workers from the source of that risk.

This is possible at the dock, and, along with proper safety training, it’s your best bet for keeping workers safe, whether they’re operating a forklift or just working nearby. Here are five engineering controls that can improve forklift/pedestrian safety at any loading dock.

5 Dock Design Choices for Forklift/Pedestrian Safety

Your first step toward pedestrian safety at the dock is to follow OSHA standard 1910.176(a), which requires sufficient clearance wherever you use mechanical material handling equipment, including lift trucks. This standard also instructs employers to label aisles and traffic lanes, and to keep travel paths clean and free of obstructions.

However, following this standard just sets the stage for a safer dock. In addition to this bare minimum, keep these tips in mind when you design (or redesign) shipping areas.

1. Wherever possible, create separate pedestrian walkways.

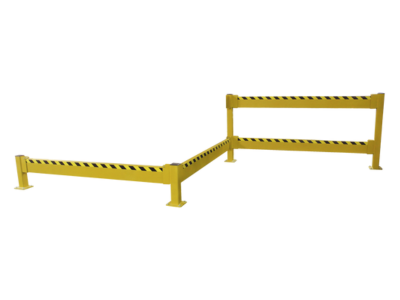

The most reliable way to keep forklifts from hitting pedestrians is to keep them far away from one another. Separate traffic lanes for lift trucks and pedestrians accomplish this goal — but floor paint is easy to ignore. Consider lining pedestrian walkways with Structural Barrier Rails designed to withstand forklift strikes.

If your dock doesn’t seem to have the space for separate walkways, try expanding capacity with a Modular Loading Dock Platform. These free-standing docking solutions essentially add an extra bay to your facility (without traditional construction).

Additionally, Dock Ramps with optional hand rails are a simple way to create dock-to-ground traffic lanes for pedestrians. You can also use Dock Ramps to create new forklift aisles between the yard and the dock, or Yard Ramps to access trailers directly. Whichever you choose, you’ll expand your working area so you have the room to establish separate traffic zones.

2. Protect pedestrian working spaces with strong barriers.

Docks aren’t always completely separated from order packing areas, assembly lines, or other pedestrian work zones. Labels alone might not be enough to keep lift trucks in their own lanes.

Keep workers safe by preventing truck access to these areas entirely. Pedestrians can easily walk around Structural Bollards, which stop most forklifts in their tracks. Structural Barrier Rails provide a machinery-safe fence for larger work areas. Use these controls to isolate lift trucks from workers on foot wherever you can.

3. Place convex safety mirrors at blind corners.

Forklift operators can’t avoid what they can’t see — and trailers create perfect blind corners every time. Depending on the layout of your loading zone, aisles may also make it hard to see oncoming traffic.

The simplest solution is to install convex safety mirrors at every blind corner. Such a tool is no substitute for human spotters, of course. According to OSHA, forklift operators should always enlist a spotter to cross blind spots. But when operators are trained to use them, mirrors can help avoid serious accidents.

4. Use barrier rails to create a short pedestrian-free zone framing dock doors.

There’s always risk when a lift truck exits a trailer, and mirrors aren’t enough to reduce the hazard. Another effective option is to frame dock doors with short barrier rails, just about the length of a forklift.

Install the barriers perpendicular to the wall, on either side of the dock door. This creates a short runway that pedestrians can’t access, giving them time to spot a lift truck emerging from a trailer before stepping into its path.

However, there’s still one more best practice we’d recommend for boosting forklift/pedestrian safety where the trailer meets the bay.

5. Install high-visibility gates at dock doors.

Forklift operators and pedestrians share one dock-related risk: falling from an open bay. Reduce this risk by making it nearly impossible to miss open dock doors — and by blocking lift truck traffic when the door’s not in use.

Powered Dock Gates present a high-visibility obstruction that keeps forklift operators and workers on foot away from dangerous ledges. It also physically blocks the exit, with a horizontal barrier that lifts with the press of a button. This solution prevents falls and roll-offs, while providing quick access when a trailer arrives.

While these tips can help to reduce risk at the dock, there’s no replacement for safety training. That’s why OSHA requires training for all forklift operators, according to safety standard 1910.178(l).

The winning combination for forklift/pedestrian safety is a well-trained workforce and a facility with robust engineering controls. To learn more about how BHS Dock Equipment can help to reduce workplace risks, contact our sales team at 1.800.247.9500.