We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Water Reclamation Systems for Compliance in Repair Shops

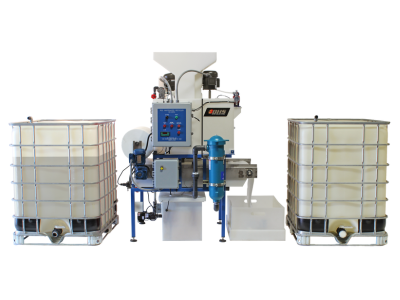

A water reclamation system cleans industrial wastewater, removing heavy metals, suspended solids, oils, greases, and more. That allows you to reuse the water on the next round of processes, or funnel it safely down the sewer. A good water reclamation system eliminates hazardous waste entirely, leaving only clean water and dried flocculant that’s suitable for standard waste streams.

Why does that matter for companies that service vehicles, agricultural equipment, and other heavy machines? Simply put, these operators create a lot of hazardous wastewater — and disposing of such fluid improperly can get you in serious trouble.

In the summer of 2023, one Vermont agricultural equipment dealer learned that lesson the hard way. Here’s a story about how maintenance and repair shops should not handle industrial wastewater, along with an introduction to a tool that eliminates this challenge.

The Hazards of Wastewater Without a Water Reclamation System

In an August 2023 newsletter, the Occupational Safety and Health Administration (OSHA) describes how an agricultural equipment dealer made a series of management mistakes surrounding wastewater and the employees that handle it.

The company’s first mistake was improper treatment of wastewater. This act alone made the company vulnerable to Environmental Protection Agency (EPA) fines of up to $25,000 per day. Ultimately, however, the dealer got in trouble for how they treated a whistleblower, the staffer who objected to dumping hazardous wastewater into a nearby river.

Servicing heavy equipment tends to create hazardous wastewater. Pollutants found in the industry’s wastewater include:

- Steam cleaning runoff

- Pressure washer effluent

- Metals and suspended solids

- Water soluble coolants

- Emulsified oils and greases

In 2022, an employee saw that the company simply pumped these substances into the banks of the Winooski River, OSHA says. The employee complained to supervisors. When that didn’t lead to changes, the employee alerted the Vermont Department of Environmental Conservation.

That act inspired management to fire the employee, who then went to OSHA with an official whistleblower claim.

OSHA investigated and found that the company violated parts of the Federal Water Pollution Control Act and the Safe Drinking Water Act. Then OSHA ordered the company to pay more than $145,000, breaking down follows:

- $45,015.72 in back wages to the wrongfully fired employee

- Interest on these back wages

- $50,000 in damages (compensatory)

- Another $50,000 in damages (punitive)

- Whistleblower attorney fees

The company also had to reinstate the employee, without prejudice. OSHA also ordered management to publicly post employee rights under the Federal Water Pollution Control Act and the Safe Drinking Water Act.

While this situation was resolved as a whistleblower case, improper handling of wastewater was the root of the problem. And a water reclamation system like the Wastewater Recycling System from BHS, Inc., could have prevented the entire affair.

How a Water Reclamation System Cleans Industrial Wastewater

If you operate a heavy vehicle shop, your wash water is probably just as contaminated as that of the agricultural equipment dealer discussed above. If you take a container of, say, runoff from a power wash and feed it into a Wastewater Recycling System, here’s what happens:

- Wastewater ente

- Agitators thoroughly mix the treatment solution with the wastewater, causing flocculation, the aggregation of pollutants into clay-based solids.

- Water flows over weirs, or small dams, separating flocculant from cleaner outflow.

- The treated water lands on a paper filter, which then automatically moves down a conveyor, exposing more clean filter surface.

- The flocculant and filter are collected in a lined catch bin.

- Meanwhile, treated water travels through a final sock filter to remove any remaining contaminants.

This process leads to two products: Clean water, suitable for reuse or sewer disposal; and a dried non-leachable, non-hazardous clay solid you can safely throw in the regular garbage. Such a process could have saved the agricultural equipment dealer in our story close to $150,000, and a ton of bad press.

When you consider a cautionary tale like that, the return on investment in a water reclamation system speaks for itself. To learn more about Wastewater Recycling Systems and other wastewater treatment equipment from BHS, Inc., contact our sales team at 1.800.247.9500.