We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Preparing Your Warehouse for a Surprise OSHA Inspection

If you operate a warehouse or distribution center, the odds of a visit from your local OSHA inspector will be a bit higher through July 2026. That’s thanks to a national program in which the Occupational Safety and Health Administration (OSHA) will pay special attention to certain logistics-related businesses, including:

- Warehouses

- Distribution centers

- Postal processing facilities

- Parcel delivery operations

- Retailers with high injury rates

This OSHA National Emphasis Program (NEP) will increase the rate of inspections, and OSHA almost never tells employers when their inspectors will show up. The only way to prepare for a surprise inspection, then, is to avoid OSHA violations in the first place.

That said, inspections conducted under the current NEP will focus on several topics in workplace health and safety. Focus your compliance efforts in the following three areas to reduce the risk of citations during your next OSHA inspection:

1. Forklift Operation

Your OSHA inspector is likely to look closely at your use of powered industrial trucks — that is, forklifts. The relevant OSHA standard here is 1910.178 - Powered industrial trucks.

|

| Lifting & Positioning |

While it’s essential to follow all applicable OSHA rules, the 2023-2026 NEP inspections will focus on storage and loading areas. That makes it particularly important to review forklift operation on docks and in the aisles. See the following articles for more detailed advice:

- Loading Dock Safety for Forklift Operators

- OSHA Guidelines for Forklift Traffic on Dock Ramps and Yard Ramps

- Managing the Forklift Center of Gravity, According to OSHA

If you operate electric forklifts, be sure to follow OSHA standards for the battery room, too. Learn more in our comprehensive, four-part series on OSHA in the battery room:

- OSHA Standards in the Battery Room - Part One: Introduction to OSHA Regulations

- OSHA Standards in the Battery Room - Part Two: OSHA 1910.178(g)

- OSHA Standards in the Battery Room - Part Three: The Rest of OSHA 1910

- OSHA Standards in the Battery Room - Part Four: Construction Industry Standards

Not sure where to start? Improve compliance — and overall productivity — with ergonomic battery handling equipment from BHS, Inc.

2. Material Handling and Storage

OSHA inspectors are also likely to investigate your material handling and storage systems. Ensure compliance with OSHA standard 1910.176 - Handling materials - general, and be aware that any unsafe condition can be cited under the General Duty Clause of the OSH act.

You can often achieve safer material handling through engineering controls, the use of material handling equipment to reduce the risk of injury to workers. For warehouses and distribution centers, that could include:

|

| Industrial Carts |

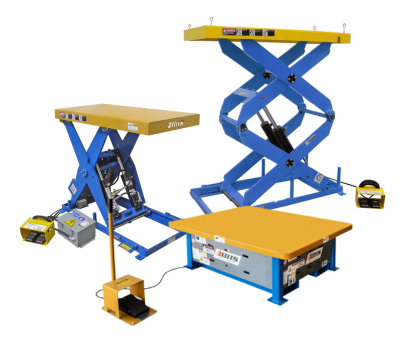

- Lift Tables and Tilt Tables that assist with lifts and position work comfortably

- Specialized Industrial Carts, designed to handle your most common materials

- Cranes and Booms for lifting and transporting heavy loads

Explore the complete selection of BHS material handling equipment, or contact us to discuss custom solutions to fit any task.

3. Ergonomic Hazards

Workplace ergonomics is the practice of altering work to reduce the risk of injury, including the musculoskeletal disorders that are all too common in material handling occupations. While OSHA doesn’t list specific ergonomic standards, inspectors may issue citations under the General Duty Clause for unsafe material handling practices.

Provide ergonomic training for all employees, and supply appropriate material handling equipment that reduces the load wherever possible. Learn more about warehouse ergonomics by reading our list of 4 Common Ergonomic Hazards in Warehouses.

Other Ways to Prepare for OSHA Inspections

While these three areas of focus can help improve OSHA compliance at your warehouse, inspectors will look for many more potential violations. The NEP for warehouses also places an emphasis on fire protection, safe floors and doors, and heat safety, for example.

All of these topics are important. The directive that outlines OSHA’s warehouse NEP points out a sobering statistic: Between 2017 and 2021, the nonfatal injury rate in the general warehousing industry was over 5 cases per 100,000 workers. In all private industries, that figure was below 3. That’s a significant difference.

By addressing every area of workplace safety, you can help to reduce injury rates at your facility — and remain prepared for a surprise OSHA inspection, whenever it may arrive.

Not sure how to improve ergonomics and throughput at your facility? Specialized material handling equipment from BHS, Inc. can help. Contact our sales team at 1.800.247.9500 to discuss your material handling needs.