We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

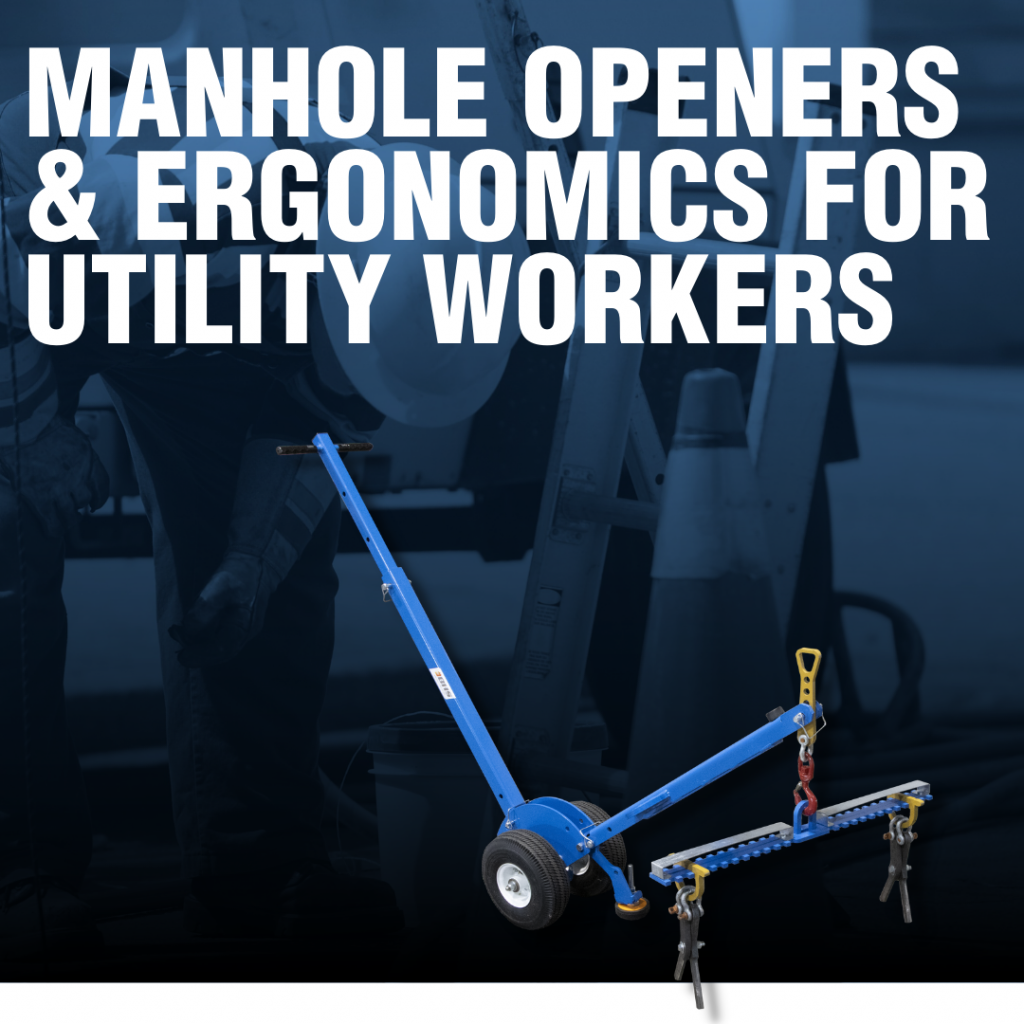

Manhole Openers and Ergonomics for Utility Workers

Manhole covers can weigh from 90 to 250 pounds or more, which is essential for ensuring safety: Heavy materials like cast iron and concrete are less susceptible to damage or accidental displacement. However, when workers need to move manhole covers, they often undertake the task without specialized equipment — which creates a serious ergonomic hazard.

While the Occupational Health and Safety Administration (OSHA) does not establish weight limits for tasks that require physical lifting, the National Institute for Occupational Safety and Health (NIOSH) has a mathematical equation for determining the risk involved in manual lifting tasks. We explain the NIOSH lifting equation in this article, but manhole covers fall into a high-risk category: They have a high load constant (the weight of the manhole cover), and manually lifting them requires awkward angles.

How to Open a Manhole (Without Sacrificing Ergonomics)

Manhole covers have several unique characteristics that makes ergonomic analysis difficult:

- Manhole lids may be infiltrated by debris like dirt, mud, and ice.

- On hot days, manhole covers may expand, increasing the force required for displacement.

- Lids are made from a variety of materials, some of which are easily damaged by basic lifting tools like pickaxes.

- The design of the manhole cover will change the necessary leverage required to lift and drag it away from the hole.

In short, this isn’t a job to leave to workers with basic tools like manhole hooks; specialized material handling equipment is absolutely essential for preventing on-the-job injuries. Here are a few basic tips for improving jobsite ergonomics and selecting appropriate equipment.

Remove debris from around the manhole cover.

Ice, dirt, and other debris will add to the force required for a successful lift. A sledgehammer or blowtorch can free up the debris; when using a blowtorch, however, workers will need to avoid applying too much heat, which can cause the manhole cover to expand.

Instruct employees to visually inspect every manhole before attempting a lift. If the lid shows clear signs of damage, standard lifting equipment may be inappropriate.

Use a manhole lifting device that can be operated at a comfortable angle.

Ideally, the worker should remain upright while operating the lifter. Bending and twisting increases the risk of a musculoskeletal injury, and the worker should be able to use their body weight to operate the device. In other words, workers shouldn’t pull or push—the force should be distributed evenly, not concentrated on the arms, shoulder, or spine.

Choose a tool designed for the job.

While manhole covers can be lifted with a pickaxe, crowbar, or hook, those tools aren’t ergonomically appropriate. Use a manhole lid lifter rated for the task.

Make sure it’s capable of handling the weight without damaging the material; the tool should lift the cover vertically, then allow it to safely move horizontally. Workers should understand how to properly secure the tool to the manhole cover by locking in the hook or other connection point.

Of course, buying the right equipment is only part of the battle: Workers must also use the device consistently. To that end, employers should look for lightweight equipment that workers can use efficiently. All employees should receive ergonomic training — remember, musculoskeletal disorders account for about 34 percent of all workplace injuries and illnesses. Investing in training and equipment helps to keep your workplace safe and productive.

Trench Lids Require Specialized Equipment

Some heavy-duty manhole cover tools are capable of lifting smaller utility trench lids, but they’re not the best choice. Trench lids have different dimensions than manhole covers, and they require a different lifting action due to their weight distribution.

The BHS Trench Lid Lifter (TLL-300) is an ergonomic solution capable of handling lids up to 300 pounds. It features a 120-degree angle between the lifting arm and handle, which allows the lid to be conveniently lifted or lowered. A built-in kickstand keeps the trench lid locked in position after the lift. To learn more about Trench Lid Lifters and other utility equipment from BHS, Inc., contact our sales team at 1.800.BHS.9500 today.