We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What Is an HMI Screen? (And How It Relates to IIoT Solutions)

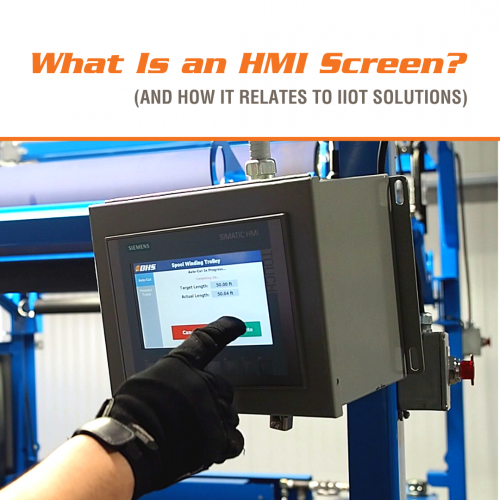

Put simply, a Human-Machine Interface (HMI) is something that allows a human to interact with a machine. That definition could apply to anything from the buttons on a calculator to the front-end software for a massive logistics management platform. However, HMIs typically refer to screen-based devices that provide a visual overview of an automated system’s processes.

HMIs grant workers instant access and control of a machine. They allow users to call up data, generate reports, and make decisions that allow the system to work more effectively. They can prevent unauthorized users from operating dangerous equipment, alert management to equipment faults, and display reports that dramatically improve throughput over time.

In short, an HMI is the part of an IIoT system that most users “see.” It’s therefore one of the most important parts of the system — even if the underlying data is sound, a poor HMI will prevent the user from utilizing that data effectively.

Key Components of an IIoT HMI Screen

To understand the importance of HMI screens, we’ll need to consider how they differ from simpler systems (e.g., mechanical controls). A digital touchscreen thermostat is an everyday example of an HMI screen. Through the screen, users can see the current temperature, make adjustments, or program the heating or cooling of their home on a specific schedule.

Obviously, in an industrial setting, an HMI screen needs to have a more robust set of features than a thermostat — but some of the same principles apply. In Industrial Internet of Things (IIoT) applications, the features of an HMI screen often include:

- Authorization Protocols - Digital safeguards can prevent unauthorized users from operating equipment or using certain features. By prompting users for identification (typically via a passcode), the HMI also collects useful information for reporting.

- Scheduling Features - Certain equipment can be scheduled to operate at set times or to prompt users to carry out essential maintenance tasks. For example, BHS Operator Aboard Battery Extractors prompt the completion of a digital Operator Daily Checklist every 24 hours, keeping the equipment in optimal condition and protecting operators in the process.

- Assignment and Order Displays - IIoT systems are designed to improve efficiency, and many HMI screens will provide workers with direct guidance for order fulfillment and other tasks.The BHS IIoT Spool Winding Trolley, for instance, has an integrated touchscreen that allows operators to choose pre-set order lengths (or enter a new one entirely). Controlled through the HMI display, the system automatically pays out the desired length.

- Reporting Capabilities - HMI screens can display basic information about a device or relay that data to another computer for centralized data collection. More data allows for better efficiency throughout the warehouse, and when data collection and reporting are mostly automatic, facilities tend to see quick results.The Operator Aboard Battery Extractor features powerful reporting capabilities, accessible via HMI screens or through smartphones, computers, and other types of devices. Reporting features are available in real time, allowing managers to make on-the-spot decisions to keep their facilities productive.

- Alert Functions - When industrial equipment operates out of expected specifications, an IIoT system can directly alert operators, giving them the opportunity to shut down the equipment.

IIoT devices save time and money while creating safer conditions for workers, and HMI screens provide the necessary interface to make the most of those improvements. To learn how IIoT solutions can improve your operation’s throughput, call our sales team at 1.800.BHS.9500.