We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

TT-952: Battery Extractor Drive Wheel Updates

Models Affected: All Operator Aboard Battery Extractors

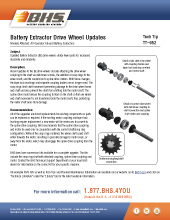

Updated Battery Extractor (BE) drive wheels utilize fewer parts for increased durability and reliability.

Description:

Recent updates to the BE drive wheels include attaching the drive wheel coupling to the shaft via dutchman screws, the addition of snap rings to the wheel shaft, and the conversion to spline drive motors. With these changes, the taper lock bushings and separate coupling bodies are no longer used. The snap rings limit shaft movement preventing damage to the drive wheel frame and shaft and also prevent the shaft from shifting into the motor shaft. The spline drive motor allows the coupling to float on the shaft so that any wheel and shaft movement is not transferred onto the motor shaft, thus protecting the motor shaft seals from damage.

Recommendation:

All of the upgrades are direct replacements for existing components so parts can be replaced as required. If the existing motor coupling and taper lock bushing require replacement, a new motor will be necessary to convert to the spline drive coupling. BHS recommends that the spline drive coupling and motor be used only in conjunction with the current shaft/snap ring configuration. Without the snap rings installed, the wheel shaft could shift either towards the motor, resulting in possible damage to motor seals, or away from the motor, which may disengage the spline drive coupling from the motor.

BHS does have conversion kits available for a complete upgrade. The kits include the snap ring shaft with attached coupling, spline drive coupling and motor. Contact the BHS Technical Support Department or your local BHS dealer for information on the correct kit for your specific machine.

All available Parts Kits as well as Tech Tips and Planned Maintenance Information are available on our website under the “Library” tab.