We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Solving the Forklift Battery Room Power Puzzle

Wouldn’t it be great if you could just plug in a forklift battery charger like a lamp? Simplifying charger installation creates a flexible, hassle-free battery room, and saves considerably on electrician’s fees — which brings us to our next point.

Managing the Forklift Battery Charging Budget

Let’s start with the most important piece of the battery room power puzzle: your budget. Hard-wiring a battery room is a huge job for a hired electrician, and that huge job will cost you. At the same time, you should never cut corners when it comes to electrical work.

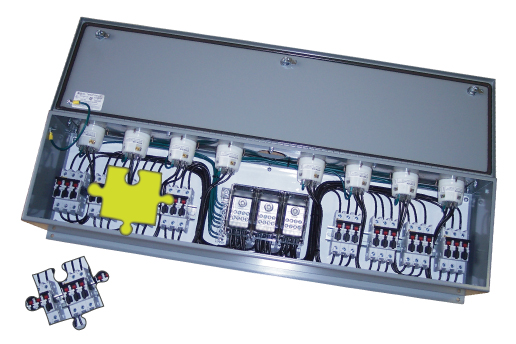

Safety-and-budget-minded managers should consider products such as the BHS Charger Power Module (PP). The Charger Power Module does much of the "hard-wiring" work that a hired electrician would do. Moreover, the Charger Power Module provides flexibility and easy disconnection for servicing battery room equipment. Compared to a hard-wired setup, this greatly reduces service and maintenance costs.

Smart Wiring for Forklift Battery Chargers

The Charger Power Module helps put this piece of the puzzle into place, too. The PP reduces the number of exposed cords and wires in the charging area. This frees-up floor space for foot traffic as well as for the general mobility of battery room staff — to say nothing of lift trucks themselves.

The BHS Charger Power Module also organizes wiring, making it much easier to manage. The PP allows for simple connections, includes matching cord plug ends to keep cabling organized, and mounts easily to charging stands.

Total Solutions for Battery Room Power

For an even more comprehensive solution for battery room wiring, consider implementing a BHS Electrical Distribution System (EDS). While the Charger Power Module makes adding and removing chargers as easy as plugging in your phone, the EDS powers an entire Operator Aboard Battery Extractor System — from the chargers to the extractor to maintenance equipment.

Products such as the BHS Charger Power Module (PP) and the EDS complement each other and create a neat, organized battery room environment. That cuts down on risk to your staff — we all know how easy it is to trip on a stray cable — as well as saving on equipment repair.

In traditional power distribution systems, managers had to keep electricians on speed-dial. With these simple but powerful solutions from BHS, battery room staff can make changes or conduct maintenance tasks on chargers whenever they want. With the puzzle complete, your battery room will make up one pretty — and efficient — picture.

References:

Kaletta, James. “Lift Trucks: Battery room safety tips.” MMH. Peerless Media LLC, 27 Oct. 2010. Web. 26 Feb. 2016.

“Powered Industrial Trucks - 1910.178.” OSHA. Occupational Safety & Health Administration, United States Department of Labor, n.d. Web. 26 Feb. 2016.

“Powered Industrial Trucks (Forklift).” OSHA. Occupational Safety & Health Administration, United States Department of Labor, n.d. Web. 26 Feb. 2016.