We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Lift Truck Fleet Rightsizing: Are Heavy-Duty Forklifts Overkill?

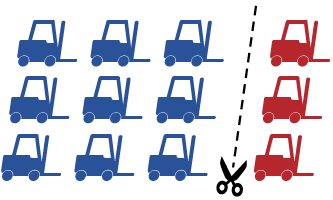

As a result, some businesses end up overpaying for their lift trucks, choosing gas- and diesel-powered units where electric power would be a much less expensive (and much more productive) option. Facilities also routinely purchase too many trucks, and underutilized fleets can be just as expensive as overutilized fleets.

If you have heavy-duty combustion forklifts, you should routinely review your fleet to determine whether or not your operation is overdue for some rightsizing. Ask yourself these questions to decide whether it’s time for a fleet audit:

-

How heavy are your heaviest loads compared to average loads?

If your heaviest loads are more than 15,000 pounds and you typically operate outdoors, you may need a combustion-powered truck or two. However, if you only handle these types of extreme loads on occasion, you may save money by running a primarily electric fleet.

Don’t purchase trucks based on your heaviest loads if your average loads are much lighter. While most analysts recommend sticking with the same lift truck models where possible (this makes maintenance much easier and ensures even wear throughout the fleet), some facilities can actually benefit from restricting their heavy-duty trucks to two or three units.

-

What do you expect to pay for fuel and maintenance?

Understanding the full costs of combustion power will help you rightsize your fleet effectively. The Electric Power Research Institute offers a calculator that allows you to easily estimate the costs of different options. Be sure to carefully gauge your annual operating hours to get accurate numbers.

-

Are maintenance costs trending upwards or downwards?

Maintenance expenses typically double after the first few years of lift truck usage.

Combustion-powered trucks have more moving components and are more susceptible to wear. They typically last for 10,000 to 20,000 hours, so you’ll need to plan to keep your combustion forklifts running. Ideally, you should incorporate major repairs (replacing electronics, motors, and transmissions every six years or so) into your budget. Electric lift trucks also require repairs, but their limited maintenance schedules mean lower expenses and less downtime.

If you’re not utilizing the full capacity of your equipment — or if you can find electric trucks that offer similar capacities — you might see a compelling reason for a full or partial fleet change.

-

Are heavy-duty lift trucks providing any gains in productivity?

Some businesses invest in Class IV and Class V forklifts because they assume that combustion power is more efficient. Several decades ago, this was a valid assumption.Fortunately, electric lift truck technology has advanced significantly, and modern battery-powered forklifts are often just as fast and capable as combustion-powered alternatives. In fact, electric trucks often provide more maneuverability and similar travel speeds without a significant drop-off in lift capacity. If you’re running especially old forklifts, improved ergonomic features are another good reason to switch — ergonomics can mean better productivity and a safer work environment for operators.

Finally, make sure that you have a plan in place to monitor lift truck utilization. Rightsizing a lift truck fleet requires data, especially if you’re gradually converting from combustion to electric; you’ll want to see exactly how much each truck costs.

For electric trucks, you can use a system like the BHS Fleet Tracker, which optimizes utilization while allowing managers to easily plan for scheduled maintenance. A computerized fleet tracking system will help you compare the costs of electric- and combustion-powered trucks within your own facility — you won’t have to rely on aggregated statistics, which might not take some factors into consideration, and you’ll be able to determine whether your heavy-duty trucks are worth the higher maintenance and fuel costs.

Resources:

Gooley, Toby. "Is Your Lift Truck Ready to Retire?" DC Velocity, 22 Apr. 2013. Web. 25 June 2015.

"Lift Truck Comparison with Capital Costs.” Electric Power Research Institute. Web. 23 June 2015.