We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

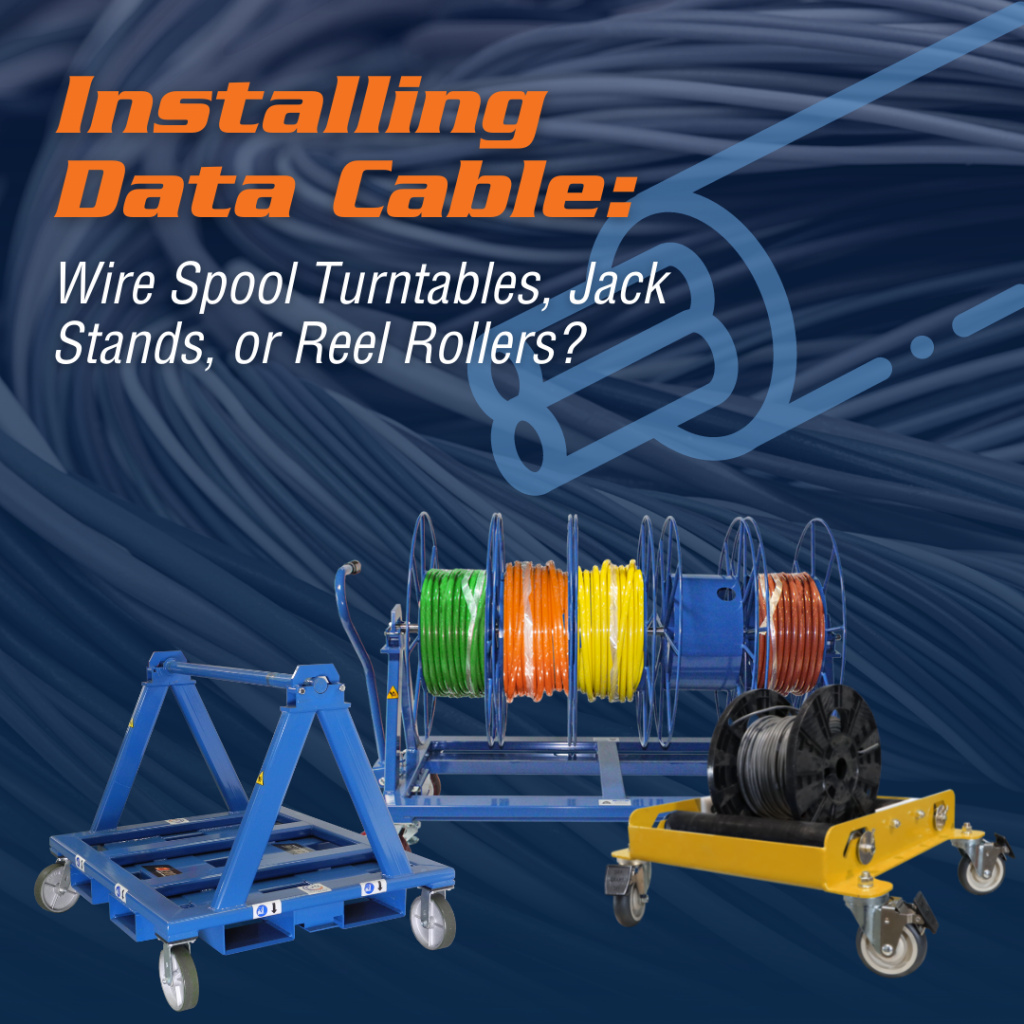

Installing Data Cable: Wire Spool Turntables, Jack Stands, or Reel Rollers?

Electricians who install low-voltage wiring face two material handling challenges to handle at once: First, they have to move data reels throughout the facility. Then they have to pull the cable. For the second of these challenges, installers have a choice between wire spool turntables, reel rollers, or traditional jack stands. But which provides the greatest benefits, in terms of both safety and productivity? The answer often depends on the extent to which payout equipment also addresses the first material handling challenge: transporting reels to the installation point.

Too often, electricians transport data cable reels manually, exposing themselves to an elevated risk of musculoskeletal disorders. The National Institute for Occupational Safety and Health (NIOSH) warns construction workers (including electricians) that they risk injury if they “often handle materials that are heavy and/or bulky, carry materials long distances, stoop downward to pick up heavy objects, or stretch upward while holding them.” Clearly, manual reel handling is a hazardous proposition.

Carts can help to reduce the risk, but moving reels from carts to stationary wire spool turntables still requires lifting and bending. Before we discuss a hybrid solution for both transporting and paying out data cable, let’s review the three leading types of payout technology available to data cable installers:

- Wire Spool Turntables. These units consist of a central spindle with four rollers arranged like a plus sign around the base. Users insert the spindle into the cable reel’s arbor hole, with one of the flanges resting on the rollers. During the pull, the spool rotates horizontally.

- Jack Stands. These pay-out solutions consist of parallel supports that hold a shaft running through the reel’s arbor hole. The most durable jack stands use A-frame supports on a unified base, although two-piece designs are also available.

- Cable Reel Rollers. A reel roller platform embeds two parallel rollers into a supportive frame. Users place reels onto the platform, often securing a shaft through the reel for stability, and pull cable as the reel rotates on the edges of its flanges.

Many of these products are stationary, requiring electricians to load them in the field. In addition to the ergonomic risks discussed above, this adds an extra task at the jobsite, reducing efficiency during data installations. BHS, Inc. provides mobile payout solutions like the Parallel Reel Payout Wagon and rolling Reel Stands — but these are high-capacity units, designed to carry multiple types of cable on heavy duty steel reels.

Standard Cat 5, Cat 6, and Cat 7 cable spools may not require such high-capacity solutions. Even more importantly, electricians may need to fit a payout solution into a tight space, especially in a data center installation. Data cable installers may obtain the greatest benefits to safety and productivity with the BHS Reel Taxi™, a portable reel roller designed specifically for data cable reels between 12 and 24 inches in diameter.

A Dual-Function Alternative to Wire Spool Turntables and Jack Stands

The Reel Taxi includes a reel roller platform that adjusts to fit data cable spools. A steel, powder-coated frame sits on four swivel casters with foot-activated brakes that lock the unit into place during pulls. An ergonomic push handle simplifies transportation — of the unit itself as well as the cable reel.

This is a small, full-service solution for installing data cable, and it answers the question of which tool is best for low-voltage wiring jobs. Wire spool turntables and jack stands may help with the pull itself, but only the Reel Taxi provides both transportation and even payout for data cable while fitting into any space. It can improve efficiency at the jobsite, while, for electrical wholesalers, it offers an enticing value add and can form the basis of a complete delivered solution. To learn more about Reel Taxis and other cable-handling equipment from BHS, Inc., contact our sales team at 1.800.BHS.9500 today.