We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Customize Lift Tables for Any Task With Tabletop Attachments

A Lift Table from BHS may be the most versatile piece of material handling equipment in your facility. These hydraulic-powered lifts incorporate into just about any production line, they allow you to create variable-height work stations for any task, and, of course, they effortlessly lift loads of up to 6,000 pounds. In short, Lift Tables are an ergonomist's dream.

Thanks to a growing line of innovative tabletop attachments, though, they're also the apple of any industrial engineer's eye. While BHS can fabricate any tabletop you can imagine, the company offers ready-made solutions for common challenges in a range of industries. These existing designs, organized by application, should get your imagination going:

-

Manufacturing -

Assembly lines are constantly evolving. When you need to move heavy materials into a milling machine or a die, for instance, a Lift Table with a Roller Conveyor (LT-RC) makes the task easy.

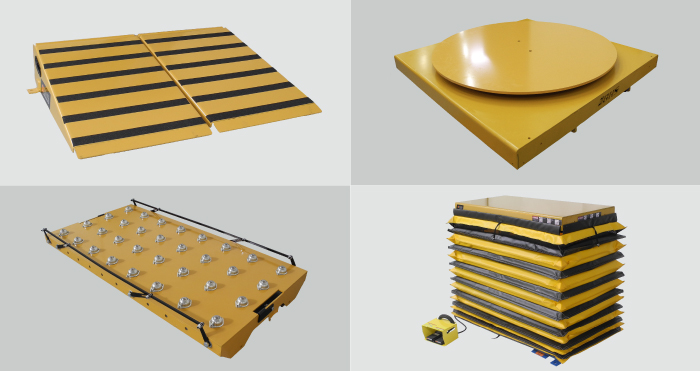

(Left to right) Loading Ramp (LT-LR), Turntable (LT-TT), Ball Transfer (LT-BT), Accordion Skirt Guard (LT-ASG)

For even more versatility moving raw materials down the line, consider a Ball Transfer (LT-BT) attachment. These powerful load-bearers simplify material movement in any direction. A single worker can rotate and send blocks of steel or wood (or anything else) to the next stop on the line, even when there's an elevation change in order.

If you work with cylindrical materials, choose a V-Frame tabletop to keep objects safely in place until they're ready to go to the next step in the production process.

-

Automotive -

Both repair garages and vehicle manufacturers share the challenge of moving large, heavy components safely around the facility. With the right tabletop attachment, Lift Tables make that task safer and more efficient.

A Turntable (LT-TT) attachment, for instance, would give workers 360 degree access to engines of virtually any size, even while seated. The fact that Lift Tables also allow staff to adjust the work zone to match their proportions makes this setup the most ergonomic way to work on engines.

Or, combine a Lift Table with the heavy duty BHS Loading Ramp (LT-LR) — you'll have a variable-height workstation for motorcycles, scooters, or anything else you can fit onto the tabletop. By the way, BHS can fabricate larger tabletops for your Lift Table, if you're getting ambitious.

-

Warehousing -

The Turntable attachment is perfect for the warehousing industry, too. One of the most common day-to-day tasks in material handling facilities is building pallets. Unloading pallets is no less common. A Self-Leveling Mobile Lift Table (SMLT) with a rotating surface is the ideal machine for working with pallet-loads.

This configuration keeps pallet-work between every worker's shoulders and waist, the area ergonomists refer to as the "golden zone." Staying within this ergonomically-friendly range of motion will cut down on strains and repetitive-motion injuries, according to OSHA guidelines.

Tabletops aren't the only accessories that can convert a Lift Table into a mission-critical part of your operation. Accordion Skirt Guards protect components from dust, metal shavings, debris, and whatever else you can throw at them. Mobile Lift Tables sit on corrosion-resistant urethane casters for total portability.

Whatever you need to get the work done, BHS can design and build a Lift Table to accomplish the task. For more information on how Lift Tables fit into virtually every industry, read our report on the subject here.

References:

Bond, Josh. “Ergonomics: Finding and maintaining the golden zone.” MMH. Peerless Media LLC, 1 Feb. 2014. Web. 23 Apr. 2016.

“Guidelines for Retail Grocery Stores.” OSHA. Occupational Safety and Health Administration, United States Department of Labor, 2004. PDF. 23 Apr. 2016.