We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

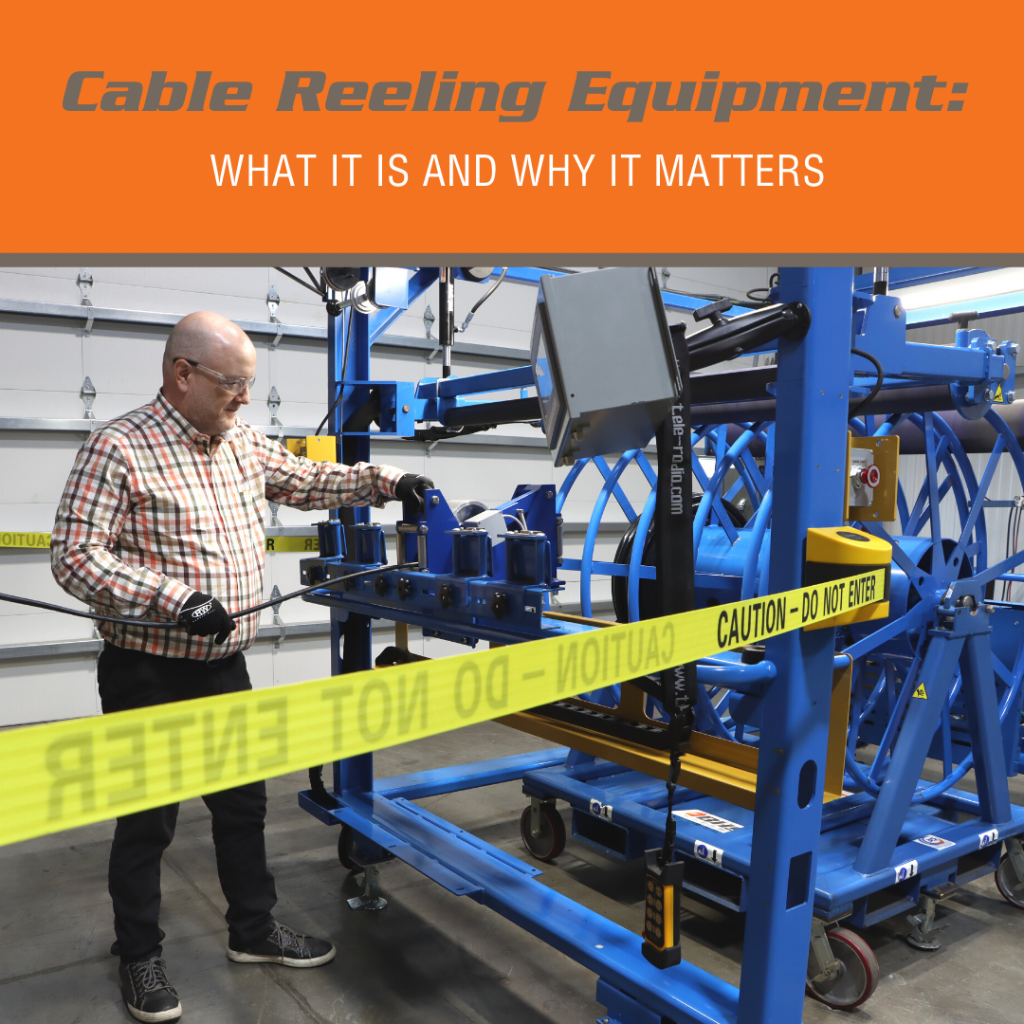

Cable Reeling Equipment: What It Is and Why It Matters

Electrical wholesalers are always looking for ways to fill cable and wire orders faster and with less risk to workers. And while cable reeling equipment has come a long way since the days of hand-cranked reeling machines, it’s still highly varied, without the sort of industry standardization we see with, say, the industrial truck market. The Occupational Safety and Health Administration classifies lift trucks into seven distinct classes; there’s no such designation for cable reeling equipment.

That can make it hard for distributors to know if their coiling, reeling, and spooling equipment is providing the greatest possible benefits. To make matters more complicated, cable and wire distributors often deliver orders of vastly different sizes and weights; not all re-spoolers can handle everything from small, light-gauge wire orders to full cable runs on heavy duty steel take-up reels. Before you can choose the right equipment, it’s helpful to consider the top designs engineers use when constructing cable reeling equipment.

Spending too much time and energy handling take-up reels? The Spool Winding Trolley fills reels where they stand, with minimal set-up time. Get the details here.

There are three basic types of cable reeling equipment:

- Traditional cable reeling equipment requires workers to secure the reel to a shaft. A motor rotates the shaft, pulling coils of material from the payout reel. Advantages: Often lower-cost, familiar to workers. Disadvantages: Requires installation of take-up reel onto loading shaft, adding material handling time to each order. These models are stationary, often with a large footprint.

- Shaftless cable reeling equipment clamps spindles onto either side of the reel, then rotates the reel directly. Advantages: Faster set-up than traditional coiling machines. Disadvantages: Installation of reels still extends order turnaround. This type of equipment is also stationary, and with cantilever arms, can require an even larger footprint than traditional cable reelers.

- Gantry cable reeling equipment uses a rolling frame and an overhead rim drive to engage cable reels on reel stands. Advantages: Mobile; travels to reels, not the other way around. Fills take-up reels directly on reel stands, making this design ideal for delivered solutions. Disadvantages: Requires reels to be loaded onto reel stands or reel roller platforms prior to operation.

If you plan to ship reels loaded onto stands or Parallel Reel Payouts—the “delivered solution,” a value-added service in which cable orders ship ready to pull—gantry-style equipment provides the greatest benefits in terms of speed, safety, and overall productivity. But regardless of which mechanical design approach works best for your operation, today’s advanced cable reelers can do much more than simply fill orders.

Like other industrial processes in the era of Big Data, cable reeling equipment can also improve accuracy and efficiency in back-office tasks like inventory management and order processing—but only if it’s wired for the Industrial Internet of Things (IIoT).

Cable Reeling Equipment and the Industrial Internet of Things

To compete in an era of increasing automation, electrical wholesalers must integrate as many data-tracking processes with the fundamentals of order fulfillment; in other words, you need cable reeling equipment that also collects and reports on data. The IIoT-enabled Spool Winding Trolley (SWT-IIoT) from BHS ships complete with an array of sensors, a touchscreen operator interface, and a 6-month subscription to the BHS SWT IIoT Portal.

Managers log in from any web-enabled device to schedule and assign orders. Operators sign in via the device touchscreen, preventing unauthorized access. Once logged in, users can call up the day’s orders and mark them filled on completion. All of this data flows into the IIoT dashboard for full reporting on order fulfillment and changing inventory levels. It’s an Industry 4.0 approach to the old industrial challenge of tracking bulk orders of cable and wire. To learn more about cable reeling equipment and other material-handling solutions for electrical wholesalers, call the BHS sales team at 1.800.BHS.9500.