We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

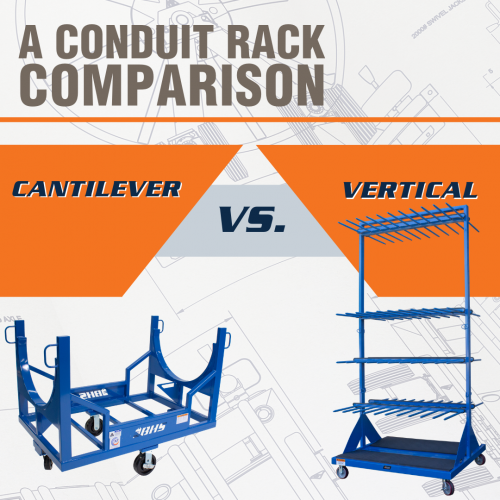

A Conduit Rack Comparison: Cantilever or Vertical?

There are as many ways to store conduit pipe as there are electrical distributors. You might leave a bundle of RMC wedged between bollards, for instance, but it wouldn’t be safe to let it roll all over the place. At any rate, a conduit rack is always better than a loose storage option.

There are two main categories of conduit racks: vertical and horizontal, or cantilever. Let’s take a look at these two major design types to see which design works best for which situation.

Here’s our rough breakdown in as few words as possible:

| Cantilever Conduit Rack | Vertical Conduit Rack | |

| Space Requirements | Moderate | Low |

| Ease of Access (Manual) | Moderate | High |

| Ease of Access (Forklift) | High | Nil |

| Stock Organization | High | High |

| Recommended Application | Bulk storage/warehousing | Small order fulfillment |

This table illustrates a key fact about choosing storage infrastructure for conduit (and any electrical supply, for that matter). Different designs are rarely “better” for all applications. Instead, they have advantages that suit them particularly well for a particular use.

With the differences between these two types of racks in mind, there are a few goals that any racking system for conduit must meet. They must:

- Provide safe, stable storage for contents at all times. This is the most important role of any racking system, and it goes double for high volume, cylindrical product like conduit.

- Comply fully with all local and OSHA regulations — e.g., 29 CFR 1910.176(b), which states that “storage of material shall not create a hazard” and that materials in storage must remain “stable and secure against sliding or collapse.”

- Keep conduit off the floor. Even the cleanest shops sometimes have spills, and even a small amount of industrial fluids can corrode conduit ends. In order to protect stock, it should be kept off of the shop floor.

- Keep different kinds of conduit separated and organized. Inventory tracking is hard enough without different SKUs getting mixed together on the shelves. Besides, clearly organized compartments prevent errors and ensure that every order ships with 100-percent accuracy.

- Protect contents from accidental strikes by lift trucks or other types of material handling equipment. Lift truck drivers might not see a bundle of conduit lying in the aisle; this is a serious safety risk. Elevating product in strong, protective racking makes the workplace safer in more ways than one.

As long as racking systems meet all the above criteria, the choice of style should depend on the application.

Comparing Vertical and Cantilever Racks for Conduit Storage

High-quality racks from trusted manufacturers will meet all of the above goals equally well. That said, each type of rack provides a different set of advantages.

Vertical Material Racks are ideal for manual picking applications. They clearly divide stock by type, and they make it easy for workers to pick individual lengths. They also fit quite nicely into order packing areas, since they make the most use of vertical space; they’re remarkably low-footprint for the volume they can hold.

Cantilever racks fit well into existing pallet rack systems, making them ideal for bulk warehousing applications. In fact, some designs are essentially pallet racks with the front columns removed. This design allows forklifts access to securely bundled loads of conduit, as well.

One final note: We recommend shipping conduit tied down in a Conduit Carrier Cart or Tilting Elevator Conduit Cart. These units provide both storage and the value-added bonus of convenient handling at the job site.

To learn more about conduit racks and other material handling solutions for electrical disributors, call the BHS sales team at 1.800.BHS.9500 today.