We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Forklift Battery Watering: Striking the Right Balance

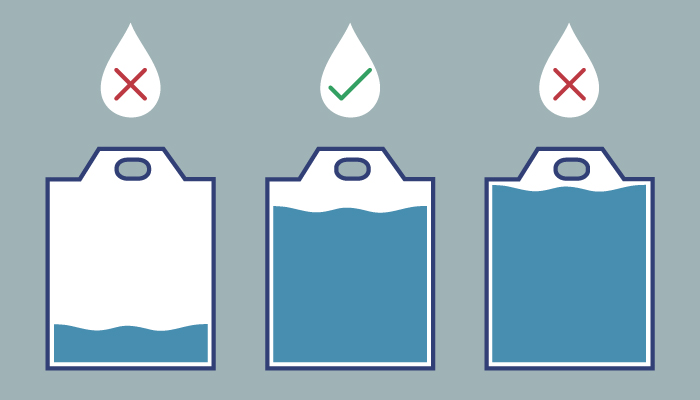

Watering forklift batteries can sometimes feel like a high-wire act. Add too much water and your risk of boil-over skyrockets; too little, and dry cell takes hold. Stray just a little in either direction, and you'll find yourself plummeting into a financial pit.

That’s because either of those outcomes will wreak havoc on battery life spans. To keep electrolyte levels perfect, establish a battery watering routine that will allow you to extract every drop of power out of your forklift batteries. Here are a few tips to get you started:

-

Choose a battery watering system that matches your fleet size.

Integrated Watering Systems are the gold standard of forklift battery watering devices. These automatic systems thread throughout your battery stands to effortlessly deliver just the right amount of water to every battery in the fleet simultaneously. A manual on/off switch adds another layer of protection against overwatering.

However, smaller battery fleets will be just fine if they're watered by hand. In fact, 70 percent of the forklift batteries in the United States are still manually watered, according to a 2015 report from industry journal Modern Materials Handling.

-

If you do water batteries by hand, empower your staff to do so effectively with the right tools.

Too often, battery watering tasks are handled by a forklift operator armed with nothing but a flashlight and a bottle. Not only does this make it impossible to gauge the water flow into cells, it can expose your staff to unacceptable ergonomic risks.

The ideal setup for watering forklift batteries by hand is a mobile Water Cart — powered either by electricity or by an internal air bladder, depending on your facility — connected to an ergonomic Water Gun.

-

Speaking of Water Guns, choose a model with an integrated level control device.

Angled Water Guns from BHS include a secure level control at the base of the nozzle. When the water level reaches its optimal height, the control will automatically shut off water flow. This device is adjustable for varying cell depths.

While water rushes into the gun with enough pressure to keep the process speedy, an internal flow diffuser softens the flow to fill batteries gently, without spillage or splashing. The Water Gun is designed to eliminate post-shutoff dripping, so your water level stays precisely where you want it.

-

Keep an eye on the water level throughout the watering process.

Most batteries operate effectively when the surface of the electrolyte falls between the separator protector at the bottom and the high watering level line at the top. It's a bit like checking your oil, but without a dipstick. Make sure to leave electrolyte between these two markers and your batteries will last longer than you ever thought possible.

-

Track watering with fleet management software.

No matter how fastidious your battery room operator is, you shouldn't leave battery maintenance schedules up to a single staff member. Among its many other benefits, fleet management software like Fleet Tracker flawlessly keeps track of watering intervals. When it's time to water batteries again, Fleet Tracker will notify staff.

Faulty watering is an expensive mistake. Every time a battery boils over, it loses three to five percent of its total runtime, according to trade publication Food Logistics. Put another way, each boil-over costs the affected battery around 20 minutes of runtime per charge. Imagine what happens when batteries are subjected to multiple boil-overs.

On the other hand, low electrolyte levels expose plates to the air, which causes dry cell. Dry cell permanently damages battery capacity. Repeat the error too many times, and you might kill a cell altogether.

Proper forklift battery watering is all a question of navigating the thin line between these two extremes. With the tools and techniques listed above, you’ll balance on that tightrope effortlessly. That’s the only way to reach the profitability that lies on the other side of the chasm.

References:

Schiavo, Brian. "It Keeps Going And Going…." Food Logistics 109 (2008): 34-35. Business Source Premier. Web. 12 Aug. 2016.

Vanasse, Harold. “Other Voices: The major impact of watering on battery room operations and maintenance.” MMH. Peerless Media LLC, 10 Sept. 2015. Web. 12 Aug. 2016.