We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Compressed Gas Safety for Warehouses and Distribution Centers

Even veteran material-handling experts break into a cold sweat when faced with a shipment of compressed gas. Gas cylinders carry unique hazards, and employees must treat them more carefully than virtually any other material in the warehouse.

To add to the challenge, gas containers are shaped awkwardly. They don't fit onto pallets or typical racks. Good luck trying to pick them up with a standard forklift or a pallet jack. Without specialized equipment, inexperienced employees may give into the temptation to move gas cylinders in dangerously improper ways.

The consequences of mishandling gas canisters are dire. In 2014 alone, pressurized containers caused 6,280 nonfatal injuries in the United States, according to the Bureau of Labor Statistics. Of those injuries, 1,700 caused the affected worker to miss more than a month of work.

Luckily, workplace safety experts from OSHA to the U.S. military have developed safe-handling standards for these dangerous materials. Working with compressed gas can be as safe as stacking pillows — you just have to know the rules and, as in every warehouse task, have the right tools for the job.

The Hazards of Handling Compressed Gas Cylinders

If you spill a pallet-load of eggs or Windex or marbles, you'll have a mess on your hands, but everyone will still get to go home at the end of the shift. If you drop canisters of compressed gas, though, your staff can end up in the hospital — or worse. In fact, mishandling gas cylinders can lead to a litany of tragic outcomes:

- Damaged valves can transform cylinders into dangerous missiles, propelled by a jet of escaping gas. Anything (and anyone) in the erratic flight path of one of these projectiles will be damaged or destroyed.

- Weakened regulators can fly off canisters like speeding bullets, with similar effects.

- On average, full gas cylinders weigh about 80 pounds. Imagine dropping that on your toe. Broken bones and serious bruises on legs and feet are the most common injuries associated with gas cylinders.

- Strains, sprains, and back injuries are the second-most common problems associated with compressed gas containers, reports occupational-safety journal EHS Today. These occur when workers try to catch a falling cylinder, which happens surprisingly often.

- The slightest crack in a cylinder's shell can lead to a serious, shrapnel-filled explosion. Some of these containers have an internal pressure of 2,500 pounds per square inch. When that kind of force bursts out in every direction, the effects rival that of a fragmentation grenade.

- Gases themselves can be dangerous. Many compressed gases are flammable, corrosive, or poisonous. Leaks in enclosed spaces can also asphyxiate workers.

Figure 1. The BHS Cylinder Transporter

(CT) provides safe and efficient handling

of industrial, compressed gas cylinders by

securing cylinders as the unit is transported

by fork pockets or casters.

Despite their inherent hazards, compressed gas is an important tool for many industries, and every industrial distribution center is likely to handle the stuff eventually. The good news is that gas cylinders are as safe as you allow them to be; a few safety rules will keep workers out of danger as they transport gas cylinders across the facility.

Safety Regulations for Transporting Compressed Gas Cylinders

The principle behind compressed gas safety is simple; handle cylinders gently. Somehow, though, you still catch workers rolling propylene canisters across the floor, or hauling a propane tank by its cap. These practices wear out gas containers, sometimes with deadly results.

Compressed Gas Association Pamphlet P-1 lists the rules for handling gas canisters in the United States. In fact, if you search the OSHA regulations for standards about compressed gas, they refer you to the CGA pamphlet. These CGA rules are legally binding.

Here are the most important CGA regulations about moving gas cylinders:

Figure 2. The BHS Cylinder Transporter Cage (CTC) is built to securely store small industrial cylinders, such as propane or propylene, and can be padlocked for optimum security.

3.2.1. Quality gas cylinders include durable, removable caps to protect valves during transportation. This rule dictates that "such caps should be kept on cylinders at all times, except when cylinders are in use."

3.2.2. This standard forbids attempts to lift cylinders "by the cap."

3.2.3. This rule outlaws dropping cylinders and letting them "strike against each other or against other surfaces violently." This one is particularly important when moving cylinders, because of their tendency to knock into one another if they aren't sufficiently secured.

3.2.4. Some workers try to move gas cylinders with existing material handling equipment. That's not a good idea, states this regulation. "Never handle a cylinder with a lifting magnet," it instructs. "Slings, ropes, or chains should not be used unless provisions have been made on the cylinder for appropriate lifting attachments, such as lugs."

However, the rule states, "a crane may be used when a safe cradle of platform is provided to hold the cylinders."

3.2.5. Here, we arrive at the ideal solution for moving gas cylinders. "It is safer to move cylinders even short distances by using a suitable truck," the rule states.

3.2.6. "Use [a] suitable hand truck, fork truck, roll platform, or similar device with cylinders firmly secured for transporting and unloading," the CGA cautions.

Pay particular attention to those last two provisions. Essentially, the CGA rules require employers to provide the "right tool for the job." Sound familiar? In this case, that tool is a dedicated gas cylinder cart, built specifically for these idiosyncratic materials.

Choosing a Gas Cylinder Cart

In order to comply with CGA rules, it's essential to choose a cylinder cart that holds gas tanks in place during travel. The Cylinder Transporter (CT) from BHS includes hinged steel retainer bars, held firmly in place with removable pins.

These retainers release quickly for immediate access, but when they're in place, they hold gas cylinders safely upright for the journey.

Heavy duty polyurethane casters limit vibration during manual travel. If you need to carry cylinders longer distances, use a forklift; the CT includes two-way fork pockets for easy travel via lift truck.

Of course, you also need a cart that you can depend on. The CT is made entirely of welded steel, and covered in a scratch- and chemical-resistant powder coat. Load it up without fear.

For outdoor applications, BHS also offers a fully caged-in gas cylinder cart. The Cylinder Transporter Cage (CTC) features the same powerful construction as the CT, but with a formed and welded steel cage to protect gas cylinders from unauthorized access. The heavy duty door hinges are welded for strength, and a strike protector defends your powerful padlock. This is an ideal option for construction sites.

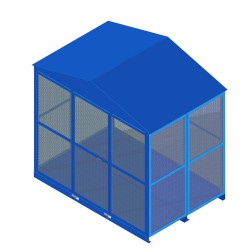

Speaking of construction sites, BHS also offers a portable Cylinder Storehouse (CSH). This welded steel structure protects gas cylinders from weather and mischief while allowing free air-flow to combat leak hazards. The CSH features a modular design that allows it to expand indefinitely, and fork pockets make it easy to place on-site.

Figure 3. The BHS Cylinder Storehouse (CSH) provides secure storage for industrial cylinders or other valuable items through its heavy-duty formed and welded frame.

Improving Compressed Gas Safety with Material Handling Equipment

January 2, 2013 started as just another day on the job for a worker at a major American gas supply company. The man, who OSHA simply calls "Employee #1" in a later Accident Report, had to get an empty nitrogen cylinder down a hallway. In the interest of efficiency, perhaps, or just absent-mindedly, he grabbed an empty cylinder cart as well.

The nitrogen cylinder was on wheels. As Employee #1 pushed it down the hallway in front of him with one hand, he pulled the empty cart behind him with the other.

Something — either debris or an imperfection in the floor; the report isn't clear — caught the cylinder's wheel. It tipped over into the empty cart, smashing Employee #1's finger in the process. Employee #1 lost that finger, the pointer on his left hand.

This tragic accident was preventable. A powerful, four-wheeled cylinder cart wouldn't have tipped over. With the capacity to carry multiple gas cylinders, the employee wouldn't have been hauling an empty cart along with his cylinder in the first place.

As awful as it is that a man lost a finger, some accidents involving gas cylinders are far worse. People have died in explosions. They've been burned by combustible leaks. The point is, gas cylinders must be treated with respect. Cylinder Transporters from BHS remove the hazards of transporting compressed gas, providing safer, more efficient material handling for this vital tool.

References:

"Accident Report Detail - 202555553 - Employee's Finger is Amputated Between Cylinder and Cart." OSHA. Occupational Safety and Health Administration, United States Department of Labor, 1 Oct. 2013. Web. 25 June 2016.

"CGA P-1: Safe Handling of Compressed Gases." CGANet. Compressed Gas Association, Incorporated, 23 Mar. 2015. Web. 25 June 2016.

"Compressed Gas Safety General Safety Guidelines." WSMR. Occupational Safety and Health Bureau, Montana Department of Labor & Industry, n.d. PDF. 25 June 2016.

Compressed gases (general requirements) - 1910.131." OSHA. Occupational Safety and Health Administration, United States Department of Labor, 7 March 1996. Web. 25 June 2016.

Davis, Bob. Practice Safety and Common Sense When Handling Compressed Gas Cylinders." EHSToday. Penton, 1 Sept. 2009. Web. 25 June 2016.

"Occupational Injuries/Illnesses and Fatal Injuries Profiles." BLS. Bureau of Labor Statistics, United States Department of Labor, n.d. Web. 25 June 2016.

"Pressurized Cylinders: The Loaded Weapon in Your Workplace." Compliance. United States Office of Compliance, Aug. 2006. Web. 25 June 2016.