We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

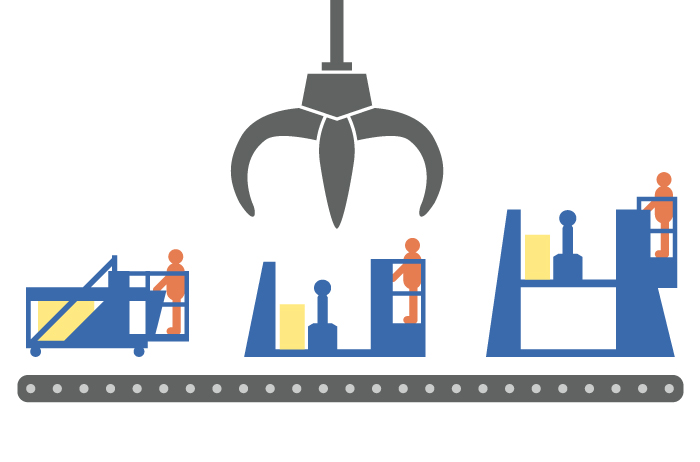

How to Choose The Right Operator Aboard Battery Extractor for Your Operation

If your forklift fleet continues to grow, the time will come when manually changing out batteries just won't make practical sense. That’s when it’s time to make the investment in an Operator Aboard Battery Extractor.

There are many types of Battery Extractors out there, and the many larger and finer points among them might seem a little bit confusing. When you're shopping for what will be such an important investment, pay close attention to these five characteristics. Finding the perfect combination of each will keep your battery room humming along at an astonishing rate.

-

The extractor arm

- Look for a T-shaped extractor arm with enclosed components. A T-shaped extractor arm, as opposed to a dangling above-battery extractor arm, is more stable and more sturdy. An extractor arm that has enclosed components will perform better and require less maintenance because contaminants won't gum it up.

-

The battery grip

- Most of today's Operator Aboard Battery Extractors use one of two technologies to grip the batteries: a vacuum cup or an electromagnet. Vacuum cups are the ideal grips because they cause much less wear and tear on batteries. However, if your fleet uses smaller-than-average batteries, you might have to choose a system that uses electromagnets.

-

The roller bed

- Some systems' roller beds are powered while other systems are free-rolling. For the safety of both your personnel and your equipment, powered roller beds are ideal. When a powered roller bed isn't rolling, it acts as a brake for batteries on the bed.

-

The lift mechanism

- There are several types of lift mechanisms available, including rack-and-pinion, tube-in-tube hydraulics, and complex lift chain systems. Look for a lift system that puts the least amount of stress on the components and has built-in safety features in case something goes wrong during a lift. One such safety feature to look for is a velocity fuse, which immediately shuts off flow when a hose breaks and keeps the carriage safely suspended.

-

The drive system

- Each and every battery change requires floor travel, so you’ll want to look for an Operator Aboard Battery Extractor that's reliable in this regard. An extractor that has dual independent motors works best because it can still run even if one of its motors requires repair. This way, the whole system isn't offline and you can schedule repair during downtime.

It's also important to pick an extractor that has a drive system that's quick and easy to service. The fewer bolts and fittings that need to be removed in order to service the drive system, the better. This will reduce downtime and prevent the orders from piling-up too much while the extractor's drive system is serviced and/or repaired.

So, keep these five basics in mind when you're comparing Operator Aboard Battery Extractors that are out there. Any good sales rep should be able to give the answers about any of these five basics. Remember that Operator Aboard Battery Extractors from BHS provide the ideal combination of these factors, and are available in models that travel up to four tiers high to accommodate battery fleets of any size.

References:

“Comparative Analysis: BHS Battery Extractors vs. the Competition.” BHS1. Battery Handling Systems, Inc., 23 Apr. 2015. Web. 6 Apr. 2016.