We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Battery Changing Solutions For Existing Pallet Trucks

Most of the published advice on forklift battery management is aimed at larger fleets. But what about the small operation — the kind that only runs one or two forklifts?

Facilities with smaller forklift fleets — even down to a single truck — probably realize that an extensive forklift battery changing system doesn't make sense for their bottom lines. After all, some users can go a couple of days without having to change out a battery. But even the single-truck facility needs an efficient means of swapping out batteries.

Instead of a full Operator Aboard Battery Extractor System, managers in lighter-duty applications opt for a pallet-truck-mounted solution, like the Automatic Transfer Carriage from BHS. Truck-mounted battery changers meet the needs of small fleets without busting the budget. This specialized battery handling equipment saves considerable time during changes, while reducing safety hazards.

Larger operations use battery transfer carriages, too. Even the biggest forklift fleets depend on at least one pallet-truck-mounted and/or lift-truck-mounted battery transfer carriage. The mobility of a truck-mounted carriage allows staff to efficiently respond to occasions when a battery needs changing outside the battery room, or during routine maintenance on the main system.

Five Ways to Transform A Pallet Truck Into a Battery Changer

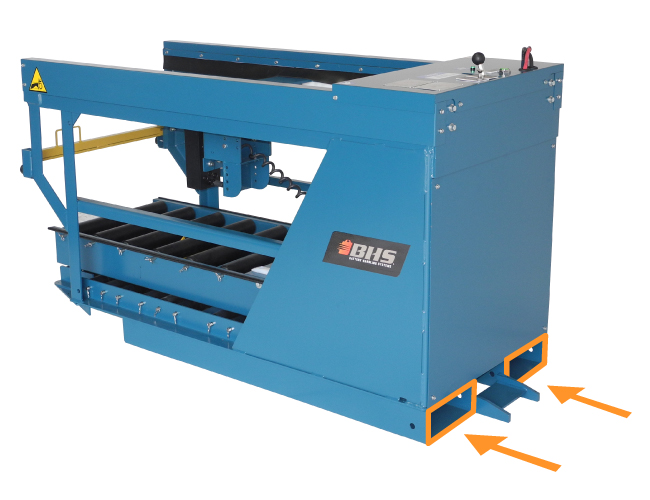

Rear-entry fork pockets are designed for use with pallet trucks.

There are five general methods of securing battery handling devices to pallet trucks. Which type is best for your operation depends on your specific needs, starting with truck availability.

-

The part-time pallet truck mount.

If you can't set aside a pallet truck just for battery changing, go with a transfer carriage that can you can load onto your lift only when you need it.

BHS' Automatic Transfer Carriage (ATC) easily attaches to and disconnects from a pallet truck. The ATC’s Fork Pocket/QDY/Tongue Kit option (ATC-FP-C-24/30, ATC-FP-C-36/42) provides an easy and flexible solution when your equipment does more than one duty. This option includes a welded tongue kit for enhanced stability and a SB quick disconnect for even more flexibility.

-

The three-way part-time pallet truck mount.

If you ever need to change a battery in a tight spot, choose a transfer carriage that allows for mounting from multiple positions.

Side-entry fork pocket are designed for use with

sit-down counterbalanced (SDCB) lift trucks.The ATC can mount to a pallet truck from three directions, which makes all the difference when you find yourself in a narrow aisle without much room to maneuver. The ATC’s Three-Way Fork Pocket/QDY (ATC-FP-3-24/30, ATC-FP-3-36/42) option integrates into pallet trucks and forklifts alike. Its rear-entry fork pockets are designed for the former, while the side-entry fork pockets are designed for use with SDCB (sit-down counter-balance) lift trucks.

-

The three-way dedicated pallet truck mount.

If an operation can dedicate a pallet truck to battery changing full-time, then it may choose to go with a more permanent connection to its full-time pallet truck host.

The ATC’s Three-Way Fork Pocket (ATC-FP-3) makes a great back-up to Operator Aboard Battery Extractors when combined with the Remote Control (ATC-RMT) and Vacuum Extraction (ATC-VAC) features. But it’s also a good choice if your operation can dedicate a pallet truck to battery changing full-time. Rear-entry fork pockets can be used with a host truck when the bolt-on Tongue Kit is attached. If you decide later to update your battery room with a higher-capacity system, then you already have your emergency backup extractor.

-

The bolt-on pallet truck mount.

Even a full-time battery changing lift may occasionally be needed for other tasks. For this reason, many users choose a bolt-on mount, which can be removed with a minimum of hassle and without specialized equipment. The ATC’s Bolt-On Mounting (ATC-BLTON) option provides a great solution for that pallet truck that sometimes has to do double-duty.

-

The permanent pallet truck mount.

Operations that can dedicate a pallet truck to battery changing full-time may want to make the transformation permanent. A factory-welded connection ensures maximum stability. The ATC’s Permanent Mounting (ATC-MPJ) option ensures that your dedicated pallet truck mount will be solid and stable. Consult the factory for this option.

So whether you run just one forklift or rely on an extensive fleet, a battery transfer carriage is an important component of your overall battery handling solution. Without one, you may be exposed to downtime and diminished efficiency during maintenance on your first-line extractor. Whether your fleet is small or large, automatic transfer carriages ensure that your facility’s forklifts stay on the go whenever you need them.

References:

Bond, Josh. “Lift Truck Management tips: Power Options — The hunt for operational efficiencies.” Logisticsmgmt. Peerless Media LLC, 1 Jan. 2013. Web. 10 March 2016.

Faust, Brian. “Proper Care, Safety and Maintenance of Forklift Batteries.” MHLNews. Penton, 21 Nov. 2014. Web. 10 March 2016.