We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Adjust the Angle of Work Surfaces to Prevent Repetitive Stress Injuries

By the Bureau of Labor Statistics' last count, musculoskeletal disorders (MSD) made up 32 percent of all workplace injuries in 2014. That number is even higher in the warehousing industry, which has the highest incidence rate for MSDs in the nation — by quite a bit.

In fact, that year saw an incidence rate of 89.9 for MSDs in the transportation and warehousing industry. The next highest rate, found in the ergonomically-challenged health care and social assistance industry, only had an MSD incident rate of 46.9.

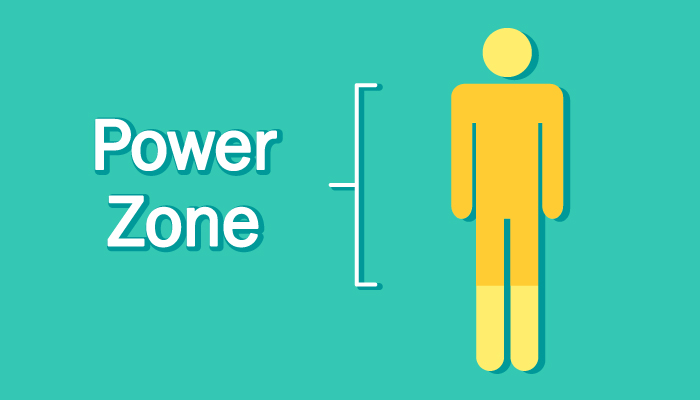

Part of the danger to warehouse staff boils down to repetitive packing and unpacking tasks. For workers who fill or empty containers, there's a simple solution to reduce the ergonomic risk-factor. If you can find a way to position work within what the Centers for Disease Control and Prevention (CDC) call the "power zone" — the space above a worker's knees, under the shoulders, and close to the body — you'll go a long way toward preventing costly and painful injuries.

Ergonomic Work Placement May Require Both Lifting And Tilting

Many containers involved in warehousing, manufacturing, and lots of other industries are so deep that they require an extra bend or stretch to access. Those are exactly the types of motions that lead to MSDs with too much repetition.

The solution is to supply Tilt Tables to employees involved in certain packing and unpacking jobs.

How Tilt Tables Prevent Ergonomic Hazards

The CDC recommends avoiding specific motions while working:

- Bending and reaching

- Lifting from the floor

- Placing repetitive stress on the back and shoulders

- Requiring large amounts of force or effort to accomplish a task

Tilt Tables move work closer to the employee's body, preventing these harmful actions. For applications that require work with large or heavy loads, a Powered Mobile Tilt Table protects workers from both repetitive stress and heavy-lifting injuries, and they're available with load capacities of up to 6,000 pounds to handle any job.

Ergonomic specialists at the CDC and NIOSH advise employers to "choose equipment appropriate for the material(s) being handled." They also recommend choosing powered equipment over its manual counterpart whenever possible. A great variety of material handling equipment is out there, and to realize the greatest ergonomic benefits, it's best to match the machine to the job as exactly as possible.

In some cases, a standard Scissor Lift Table will do just fine. But for certain tasks, such as emptying containers, ergonomic work positioning isn't always just about the level of the working surface. Sometimes, it's also about the angle.

References:

"Ergonomic Guidelines for Manual Material Handling." CDC. National Institute for Occupational Safety and Health (NIOSH), Centers for Disease Control and Prevention, 2007. PDF. 30 Apr. 2016.

"News Release: Nonfatal Occupational Injuries and Illnesses Requiring Days Away From Work, 2014." BLS. Bureau of Labor Statistics, U.S. Department of Labor, 19 Nov. 2015. PDF. 30 Apr. 2016.